API 6A Type 6BX 20000 PSI Blind & Weld Neck Flanges

Table of Content

- API 6A Flanges Manufacturer | API 20000 Blind & Weld Neck Flanges

- API 6A Type 6BX 20000 PSI Blind & Weld Neck Flanges Dimensions

- Specification of API 6A Type 6BX 20000 PSI Blind & Weld Neck Flanges

- Advantages of Using API 6A Type 6BX 20000 PSI Weld Neck Flanges

- Applications of API 6A Type 6BX 20000 PSI Weld Neck Flanges

- Supply and Exporter of API 6A Type 6BX 20000 PSI Blind & Weld Neck Flanges

- FAQ

API 6A Type 6BX 20000 PSI Blind & Weld Neck Flanges Manufacturers & suppliers in India

High pressure steel flange, forged flanges, API 6A Type 6BX 20000 PSI Blind & Weld Neck Flanges Stockholders

API 6A Flanges Manufacturer | API 20000 Blind & Weld Neck Flanges Supplier

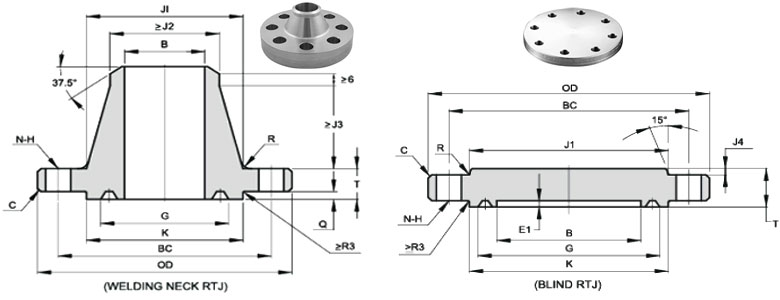

API 6A Type 6BX 20000 PSI Blind & Weld Neck Flanges Dimensions

| Size | B | OD | C | E1 | Q | G | K | T | J1 | J2 | J3 | J4 | R | BC | N | H | BX |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 13/16″ | 46.8 | 255 | 3 | – | 5.56 | 77.77 | 117 | 63.5 | 133.4 | 109.5 | 49.2 | – | 10 | 203.2 | 8 | 29 | 151 |

| 2 1/16″ | 53.2 | 285 | 3 | – | 5.95 | 86.23 | 132 | 71.5 | 154 | 127 | 52.4 | – | 10 | 230.2 | 8 | 32 | 152 |

| 2 9/16″ | 65.9 | 325 | 3 | – | 6.75 | 102.77 | 151 | 79.4 | 173 | 144.5 | 58.7 | – | 10 | 261.9 | 8 | 35 | 153 |

| 3 1/16″ | 78.6 | 355 | 3 | – | 7.54 | 119 | 171 | 85.8 | 192.1 | 160.3 | 63.5 | – | 10 | 287.3 | 8 | 39 | 154 |

| 4 1/16″ | 104 | 445 | 3 | – | 8.33 | 150.62 | 219 | 106.4 | 242.9 | 206.4 | 73 | – | 10 | 357.2 | 8 | 48 | 155 |

| 7 1/16″ | 180.2 | 655 | 6 | 11.1 | 11.11 | 241.83 | 352 | 165.1 | 385.8 | 338.1 | 96.8 | 7.9 | 16 | 554 | 16 | 54 | 156 |

| 9 “ | 229.4 | 805 | 6 | 12.7 | 12.7 | 299.06 | 441 | 204.8 | 481 | 428.6 | 107.9 | 6.4 | 25 | 685.8 | 16 | 67 | 157 |

| 11″ | 280.2 | 885 | 6 | 14.3 | 14.29 | 357.23 | 505 | 223.9 | 566.7 | 508 | 103.2 | 12.7 | 25 | 749.3 | 16 | 74 | 158 |

| 13 5/8″ | 346.9 | 1160 | 6 | 15.9 | 15.88 | 432.64 | 614 | 292.1 | 693.7 | 628.6 | 133.3 | 14.2 | 25 | 1016 | 20 | 80 | 159 |

Specification of API 6A Type 6BX 20000 PSI Blind & Weld Neck Flanges

| Specification | Description |

| Standard | API 6A |

| Flange Type | Blind Flange, Weld Neck Flange |

| Pressure Rating | 20000 PSI |

| Materials Available | Carbon Steel, Stainless Steel (304, 316, 310, 410), Duplex Stainless Steel (2205, 2507), Monel (400, 500), Hastelloy |

| Connection Type | Raised Face (RF), Ring Type Joint (RTJ) |

| Sizes Available | 1/2″ to 48″ |

| Standards | ANSI, ASME, DIN, JIS, API |

| Applications | High-pressure and high-temperature industrial applications, oil and gas industry, petrochemical industry, etc. |

Advantages of Using API 6A Type 6BX 20000 PSI Weld Neck Flanges

Weld neck flanges offer significant advantages over other types of flanges, such as slip-on flanges. Here are the key benefits of using weld neck flanges:

- Superior Strength

Weld neck flanges feature a long tapered hub, providing additional strength to the connection between the pipe and the flange. The welding process creates a durable and permanent bond capable of withstanding high pressures and extreme temperatures. - Versatility in Accommodating Different Pipe Sizes

Available in various sizes, weld neck flanges are suitable for use with pipes of different diameters. They can also be used with pipes made from different materials, including stainless steel, carbon steel, and alloy steel, offering flexibility for diverse applications. - Secure and Leak-Free Connection

The welding process ensures a strong, leak-free connection between the pipe and the flange. This enhances the safety and efficiency of the piping system by reducing the risk of leaks and other potential hazards. - Easy Installation and Maintenance

Weld neck flanges are relatively easy to install, with the welding process being completed quickly. They also require minimal maintenance, with periodic inspections ensuring they remain in good working condition

Applications of API 6A Type 6BX 20000 PSI Weld Neck Flanges

Weld neck flanges are essential components in various industrial piping systems. Here are some key applications:

- Oil and Gas Industry

In the oil and gas sector, weld neck flanges are crucial for transporting crude oil, natural gas, and other petroleum products, ensuring reliable and safe connections in high-pressure environments. - Chemical Processing Industry

Weld neck flanges are widely used in chemical processing plants to transport a variety of chemicals and materials, providing secure and leak-free connections that can handle corrosive substances. - Water Treatment Industry

In water treatment facilities, weld neck flanges are used to convey water and other fluids, offering durability and resistance to pressure changes, which is vital for maintaining system integrity. - Power Generation Industry

Weld neck flanges are utilized in power plants to transport steam, gas, and other fluids, ensuring efficient and safe operations under high pressure and temperature conditions.