Monel Products

Monel Pipe, Monel 400, Wholesale Supplier of Monel Products, Monel k500, Manufacturer of Monel Products in India.

Monel Suppliers, Monel Metal, Monel 400 Suppliers, Wholesale Trader of Monel Products, Monel Material Trader In Europe.

Kalpataru Piping Solutions is a trusted manufacturer and supplier of high-quality Grade 400 and K500 products, including Monel flanges, pipe fittings, pipes, and tubes. Our products are widely used in various industries and are exported to numerous international markets, including the USA, UK, UAE, and several European countries. We are committed to delivering top-notch products that meet the specific needs of our global clients.

Types of Duplex Steel product

About Monel and its Uses

Monel is a group of nickel alloys, mainly composed of nickel (up to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. These alloys are known for their exceptional strength and resistance to corrosion, making them ideal for demanding environments such as marine settings, chemical processing, and the aerospace industry.

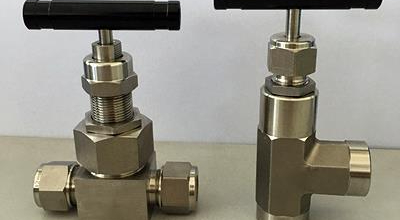

Monel products are widely utilized across various industries such as oil and gas, chemical processing, marine engineering, and aerospace. The Grade k400 and K500 Monel alloys stand out for their superior resistance to corrosion and erosion, making them particularly well-suited for applications in seawater environments. These properties ensure reliable performance and longevity in demanding conditions.

Properties of Monel

Monel is a solid-solution binary alloy with excellent mechanical properties, even at temperatures below zero degrees Fahrenheit. Monel Alloy 400, in particular, has a Poisson ratio of 0.32 and a specific gravity of 8.80. The melting range for Monel Alloy 400 is between 1300 and 1350°C. Below is a table summarizing the properties of Monel Alloy 400 at room temperature:| Form | Condition | Tensile Strength (ksi) | Yield Strength (ksi) | % Elongation | Brinell hardness | Rockwell B Hardness | Tensile Strength (Mpa) | Yield Strength (Mpa) |

| Rod and Bar | Annealed | 75-90 | 25-50 | 60-35 | 110-149 | 60-80 | 517-620 | 172-345 |

| Rod and Bar | Hot-Finished (except Hexagons over 2 1/8 inches and Angles) | 80-110 | 40-100 | 60-30 | 140-241 | 75-100 | 552-758 | 276-690 |

| Rod and Bar | Hot-Finished Hexagons over 2 1/8 inches and Angles | 75-100 | 30-55 | 50-30 | 130-184 | 72-90 | 517-690 | 207-379 |

| Rod and Bar | Cold-Drawn, Stress-Relieved | 84-120 | 55-100 | 40-22 | 160-225 | 85-20C | 579-827 | 379-690 |

| Plate | Hot Rolled | 75-95 | 40-75 | 45-30 | 125-215 | 70-96 | 517-655 | 276-517 |

| Plate | Hot Rolled, Annealed | 70-85 | 28-50 | 50-35 | 110-140 | 60-76 | 482-586 | 193-345 |

| Sheet | Annealed | 70-85 | 30-45 | 45-35 | 65-80 | 482-586 | 207-310 | |

| Sheet | Cold Rolled, hard | 100-120 | 90-110 | 15-02 | Min. 93 | 690-827 | 621-758 | |

| Cold Rolled Strip | Annealed | 70-85 | 25-45 | 55-35 | Max. 68 | 482-586 | 172-310 | |

| Cold Rolled Strip | Spring Temper | 100-140 | 90-130 | 15-02 | Min. 98 | 690-965 | 621-896 | |

| Seamless pipe and tube | Cold Drawn, Annealed | 70-85 | 25-45 | 50-35 | Max 75 | 482-586 | 172-310 | |

| Seamless pipe and tube | Cold Drawn, Stress Relieved | 100-140 | 55-100 | 35-15 | 85-100 | 586-827 | 379-690 | |

| Cold Drawn Wire | Annealed | 70-95 | 30-55 | 45-25 | 482-655 | 207-379 |

Mechanical Properties of Monel alloy 400 at Room Temperature

Monel Alloy 400 has distinct mechanical properties that make it suitable for various industrial applications, but these properties also present certain challenges during machining, welding, forging, and hot working.

- Machinability: Monel Alloy 400 becomes harder as it is worked on, making it difficult to machine. However, it can be machined using techniques similar to those used for iron.

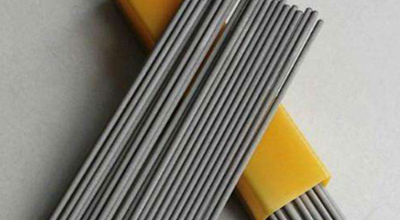

- Welding: Monel can be effectively welded using several methods, including gas-arc welding, gas-metal-arc welding, metal-arc welding, and submerged-arc welding.

- Forging: Monel Alloy 400 can be forged, but specific conditions must be met to ensure the best results.

- Hot Working: The typical temperature range for hot working Monel Alloy 400 is between 648°C and 1176°C (1200°F to 2150°F).

Grades of Monel

|

Monel Grade/Trade Name |

ASTM/AISI Alloy Type |

UNS No. |

%Ni |

%Cu |

%Fe |

%Mn |

%Al |

%Ti |

%Si |

|

Monel 400 |

B 127/ B 164 |

N04400 |

Min. 63 |

28-34 |

Max 2.5 |

Max 2.0 |

|

|

Max 0.5 |

|

Monel 401 |

|

N04401 |

Min. 63 |

28-34 |

Max 2.5 |

Max 2.0 |

|

|

Max 0.5 |

|

Monel 404 |

|

N04404 |

52-57 |

Remaining |

Max 0.5 |

Max 0.1 |

Max 0.05 |

|

Max 0.1 |

|

Monel 405 |

B 164 |

N04405 |

Min. 63 |

28-34 |

Max 2.5 |

Max 2.0 |

|

|

Max 0.5 |

|

Monel K500 |

B 865 |

N05500 |

Min. 63 |

27-33 |

Max 2.0 |

Max 1.5 |

2.3-3.15 |

0.35-0.85 |

Max 0.5 |

We Export To Monel Products

New Zealand, Ukraine, Brazil, Azerbaijan, Angola, United Kingdom, Philippines, Oman, France, Algeria, Macau, Sri Lanka, Tibet, Norway, Mexico, Venezuela, Denmark, Russia, Bhutan, Estonia, Austria, Vietnam, Argentina, Turkey, Greece, Romania, Bahrain, Bangladesh, Afghanistan, Italy, Poland, Zimbabwe, Thailand, India, Kenya, Ecuador, Puerto Rico, Nepal, Malaysia, Bulgaria, Libya, Slovakia, Chile, Serbia, Australia, Poland, Iran, Costa Rica, Peru, South Korea, Iraq, Iran, Indonesia, Spain, Trinidad & Tobago,Tunisia, Qatar, Japan, Canada, Taiwan, Yemen, Mongolia, Czech Republic, Israel, Ghana, Egypt, Nigeria, Saudi Arabia, United Arab Emirates, Namibia, Hungary, South Africa, Hong Kong, Croatia, Colombia, Lebanon, Nigeria, Portugal, Finland, Pakistan, Jordan, Sweden, Belgium, Gambia, Lithuania, United States, Chile, Bolivia, Germany, Singapore, Ireland, Gabon, Kuwait, Switzerland, Mexico, Belarus, Kazakhstan, Morocco, China, Netherlands, Germany, Belgium, Italy, Turkey, Denmark and UK.

FAQ

What is Monel used for?

Monel is a versatile alloy primarily used in marine engineering, chemical and hydrocarbon processing equipment, valves, pumps, shafts, fittings, fasteners, and heat exchangers due to its excellent corrosion resistance. Additionally, it is utilized in making metal instruments and eyeglass frames.

What is Monel Material?

Monel is a group of nickel-copper alloys, first developed in 1905, typically composed of about 66% nickel and 31.5% copper, with small amounts of iron, manganese, carbon, and silicon. It is stronger than pure nickel and highly resistant to corrosion, particularly in environments like rapidly flowing seawater.

What is Monel Metal Composition?

Monel metal is composed primarily of nickel (ranging from 52% to 67%) and copper, along with small amounts of iron, manganese, carbon, and silicon. It is distinct from cupro nickel alloys due to its lower copper content, typically less than 60%.

Related Products

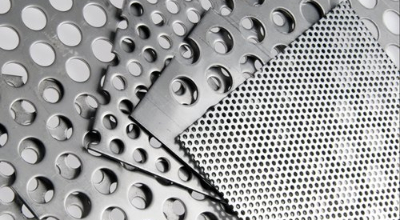

- Duplex Steel UNS S31803 Plates and Duplex Steel UNS S31803 Sheets

- Duplex Steel UNS S32205 Plates and Duplex Steel UNS S32205 Sheets

- Duplex Steel UNS S31803 Buttweld Fittings

- Duplex Steel UNS S32205 Buttweld Fittings

- Duplex Steel UNS S31803 Forged Fittings

- Duplex Steel UNS S32205 Forged Fittings

- Duplex Steel UNS S32205 Instrumentation Valve