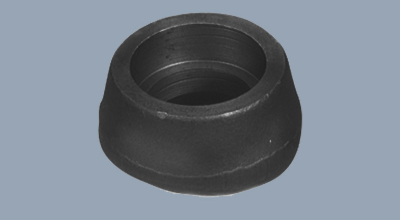

Alloy Steel Olets Product

ASTM A182 F9 Alloy Steel Olet Fittings, ASME SA182 Alloy Steel Threaded Pipe Outlets, A182 F91 Alloy Steel Outlets Pipe Fittings, Alloy Steel Flangeolet, A182 Gr. F22 Alloy Steel Branzolet Price in Europe.

Kalpataru Piping Solutions supplies Alloy Steel Olets worldwide at competitive prices. Our A182 F5 Alloy Steel Olets incorporate various metals to enhance corrosion resistance and overall durability. They are particularly favored in critical operations within aerospace and nuclear sectors for their flexibility and superior mechanical properties, ensuring optimal performance.

As a renowned manufacturer of Alloy Steel Branch Connection Fittings, we cater to diverse industrial applications with a wide range of grades, sizes, and dimensions across all materials. Our Alloy Steel F9 Elbolets are known for their responsiveness to heat treatments like annealing and normalizing, offering enhanced performance characteristics.

We maintain a comprehensive inventory of Alloy Steel ASTM A182 Olets, including A182 F5 Alloy Steel Weldolets, Alloy Steel F9 Threadolets, A182 F11 Sockolets, A182 F91 Alloy Steel Nipp olets, A182 F12 Alloy Steel Elbolets, and Alloy Steel F22 Latrolets, among others.

Types of Alloy Steel Olets

Specifications of Alloy Steel Olets

| Specifications | ASTM A182 & ASME SA182 |

| Connect Type | Welded, threaded, BW, SW |

| Dimensions | ASME/ANSI B16.11, MSS-SP-97, MSS-SP-79, JIS B2316, BS 3799 etc |

| Grades | A182 GR F5, F9, F11, F12, F22, F91. |

| Size | 1/8″-4″ (DN6-DN100) |

| Process | Free forging, plate cutting .forged |

Manufacturing Standards of Alloy Steel Weldolets

| ASTM A182 / ASME SA182 | Standard Specification for Wrought Austenitic Steel Piping Fittings |

| ASME B16.11 | Forged Fittings Socket – Welding and Threaded |

| MSS SP-97 | Integrally Reinforced Forged Branch Outlet Fittings – Socket Welding, Threaded and Buttwelding Ends |

ASTM A182 Alloy Steel Olets Dimensions

| Schedule STD | |||||

| Size | Size in mm | Height A | OD -B | Hole Dia C | Weight in KG |

| 1/4 | 8 | 14.3 | 25.4 | 15.9 | 0.04 |

| 3/8 | 10 | 19.05 | 31.75 | 19.05 | 0.07 |

| 1/2 | 15 | 19.05 | 34.93 | 23.81 | 0.08 |

| 3/4 | 20 | 22.23 | 44.45 | 30.16 | 0.11 |

| 1 | 25 | 26.99 | 53.98 | 36.51 | 0.23 |

| 1 1/4 | 32 | 31.75 | 65.09 | 44.45 | 0.36 |

| 1 1/2 | 40 | 33.34 | 73.03 | 50.8 | 0.45 |

| 2 | 50 | 38.1 | 88.9 | 65.09 | 0.79 |

| 2 1/2 | 65 | 41.28 | 103.19 | 76.2 | 1.13 |

| 3 | 80 | 44.45 | 122.24 | 93.66 | 1.81 |

| 3 1/2 | 90 | 47.63 | 142.88 | 112.71 | 2.5 |

| 4 | 100 | 50.8 | 152.4 | 120.65 | 2.86 |

| 5 | 130 | 57.15 | 179.3 | 141.29 | 4.65 |

| 6 | 150 | 60.33 | 215.9 | 169.86 | 6.44 |

| 8 | 200 | 69.85 | 263.53 | 220.66 | 10.66 |

| 10 | 250 | 77.79 | 322.26 | 274.64 | 17.69 |

| 12 | 300 | 85.73 | 377.83 | 325.44 | 26.76 |

| 14 | 350 | 88.9 | 409.58 | 357.19 | 29.94 |

| 16 | 400 | 93.6 | 463.55 | 407.99 | 34.02 |

| 18 | 450 | 96.84 | 520.7 | 458.79 | 44 |

| 20 | 500 | 101.6 | 571.5 | 508 | 53.52 |

| 24 | 600 | 144.5 | 717.5 | 609.6 | 101 |

| 26 | 650 | 155.6 | 778 | 660.4 | 120 |

| 30 | 750 | 174.6 | 893.6 | 762 | 190 |

| 36 | 900 | 206.4 | 1070 | 914.4 | 310 |

| 40 | 1000 | 225.4 | 1187.6 | 1016 | 435 |

| 42 | 1050 | 235 | 1244.6 | 1066.8 | 540 |

| 48 | 1200 | 241.3 | 1404 | 1219.2 | 750 |

| Schedule XS | |||||

| Size | Size in mm | Height – A | OD – B | Hole Dia – C | Weight in KG |

| 1/4 | 8 | N/A | 25.4 | 15.88 | 0.05 |

| 3/8 | 10 | N/A | 31.75 | 19.05 | 0.07 |

| 1/2 | 15 | 19.05 | 34.93 | 23.81 | 0.09 |

| 3/4 | 20 | 22.23 | 44.45 | 30.16 | 0.14 |

| 1 | 25 | 26.99 | 53.98 | 36.51 | 0.21 |

| 1 1/4 | 32 | 31.75 | 65.09 | 44.45 | 0.41 |

| 1 1/2 | 40 | 33.34 | 73.03 | 50.8 | 0.5 |

| 2 | 50 | 38.1 | 88.9 | 65.09 | 0.79 |

| 2 1/2 | 65 | 41.28 | 103.19 | 76.2 | 1.18 |

| 3 | 80 | 44.45 | 122.24 | 93.66 | 1.86 |

| 3 1/2 | 90 | 47.63 | 136.53 | 112.71 | 2.54 |

| 4 | 100 | 50.8 | 152.4 | 120.65 | 2.9 |

| 6 | 150 | 77.79 | 225.43 | 169.86 | 10.43 |

| 8 | 200 | 98.43 | 292.1 | 220.66 | 16.78 |

| 10 | 250 | 93.66 | 323.85 | 265.11 | 20.87 |

| 12 | 300 | 103.1 | 379.41 | 317.5 | 27.67 |

| 14 | 350 | 100.01 | 431.8 | 350.84 | 31.75 |

| 16 | 400 | 106.36 | 466.73 | 403.23 | 46.27 |

| 18 | 450 | 111.13 | 523.88 | 455.61 | 58.97 |

| 20 | 500 | 119.06 | 582.61 | 509.59 | 71.67 |

| 24 | 600 | 152.4 | 722.2 | 609.6 | 142 |

| 26 | 650 | 165.1 | 782.6 | 660.4 | 168 |

| 30 | 750 | 181 | 896.8 | 762 | 218 |

| 36 | 900 | 212.7 | 1074.4 | 914.4 | 404 |

| 40 | 1000 | 235 | 1194 | 1016 | 582 |

| 42 | 1050 | 244.5 | 1250.8 | 1066.8 | 590 |

| 48 | 1200 | 273 | 1425.6 | 1219.2 | 910 |

| Schedule XXS | |||||

| Size | Size in mm | Height – A | OD – B | Hole Dia – C | Weight in KG |

| 1/2 | 15 | 28.58 | 34.93 | 14.29 | 0.11 |

| 3/4 | 20 | 31.75 | 44.45 | 19.05 | 0.32 |

| 1 | 25 | 38.1 | 50.8 | 25.4 | 0.38 |

| 1 1/4 | 32 | 44.45 | 61.91 | 33.34 | 0.57 |

| 1 1/2 | 40 | 50.8 | 69.85 | 38.1 | 0.79 |

| 2 | 50 | 55.56 | 80.96 | 42.86 | 0.97 |

| 2 1/2 | 65 | 61.91 | 96.84 | 53.98 | 1.53 |

| 3 | 80 | 73.03 | 120.65 | 73.03 | 2.87 |

| 4 | 100 | 84.14 | 152.4 | 98.43 | 4.76 |

| 5 | 130 | 93.66 | 187.33 | 122.24 | 6.46 |

| 6 | 150 | 104.78 | 220.66 | 146.05 | 12.7 |

| 8 | 200 | 111.12 | 284.16 | 173.04 | 20.41 |

| 10 | 250 | 125.41 | 312.74 | 215.9 | 38.56 |

| Schedule 160 | |||||

| Size | Size in mm | Height – A | OD – B | Hole Dia – C | Weight in KG |

| 1/2 | 15 | 28.58 | 34.93 | 14.29 | 0.11 |

| 3/4 | 20 | 31.75 | 44.45 | 19.05 | 0.32 |

| 1 | 25 | 38.1 | 50.8 | 25.4 | 0.38 |

| 1 1/4 | 32 | 44.45 | 61.91 | 33.34 | 0.57 |

| 1 1/2 | 40 | 50.8 | 69.85 | 38.1 | 0.79 |

| 2 | 50 | 55.56 | 80.96 | 42.86 | 0.97 |

| 2 1/2 | 65 | 61.91 | 96.84 | 53.98 | 1.53 |

| 3 | 80 | 73.03 | 120.65 | 73.03 | 2.87 |

| 4 | 100 | 84.14 | 152.4 | 98.43 | 4.76 |

| 5 | 130 | 93.66 | 187.33 | 122.24 | 6.46 |

| 6 | 150 | 104.78 | 220.66 | 146.05 | 12.7 |

| 8 | 200 | 111.12 | 284.16 | 173.04 | 20.41 |

| 10 | 250 | 125.41 | 312.74 | 215.9 | 38.56 |

Applications of Alloy Steel Olets

Olets find application across various industrial sectors for their versatility and efficiency in piping systems. Here are some key industries where alloy steel olets are extensively used:

- Petrochemical

- Oil & Gas

- Pulp & Paper

- Refineries

- Nuclear Power

- Cement

- Sugar

- Power Plants

- Fertilizers

- Breweries

- Chemicals

- Shipbuilding

- Defense

- Mining

- Steel Plants

- Construction

- Oil Mills

- Engineering Companies

These industries utilize Alloy Steel Olets to facilitate efficient branching and connections in piping networks, ensuring reliable performance and operational integrity.

We Export To Alloy Steel Olets

New Zealand, Ukraine, Brazil, Azerbaijan, Angola, United Kingdom, Philippines, Oman, France, Algeria, Macau, Sri Lanka, Tibet, Norway, Mexico, Venezuela, Denmark, Russia, Bhutan, Estonia, Austria, Vietnam, Argentina, Turkey, Greece, Romania, Bahrain, Bangladesh, Afghanistan, Italy, Poland, Zimbabwe, Thailand, India, Kenya, Ecuador, Puerto Rico, Nepal, Malaysia, Bulgaria, Libya, Slovakia, Chile, Serbia, Australia, Poland, Iran, Costa Rica, Peru, South Korea, Iraq, Iran, Indonesia, Spain, Trinidad & Tobago,Tunisia, Qatar, Japan, Canada, Taiwan, Yemen, Mongolia, Czech Republic, Israel, Ghana, Egypt, Nigeria, Saudi Arabia, United Arab Emirates, Namibia, Hungary, South Africa, Hong Kong, Croatia, Colombia, Lebanon, Nigeria, Portugal, Finland, Pakistan, Jordan, Sweden, Belgium, Gambia, Lithuania, United States, Chile, Bolivia, Germany, Singapore, Ireland, Gabon, Kuwait, Switzerland, Mexico, Belarus, Kazakhstan, Morocco, China, Netherlands, Germany, Belgium, Italy, Turkey, Denmark and UK.

FAQ

What are olets used for?

Olet fittings, also known as branch connection fittings or outlet fittings, serve to create a branch from a larger pipe to a smaller one, or to a pipe of the same size. The main pipe onto which the branch connection is welded is typically referred to as the run or header size.

What are olets?

Olets are self-reinforced branch connections used in piping systems to provide an outlet from a larger pipe to a smaller one or to a pipe of the same size. They include various types such as Weldolet, Sockolet, Elbolet, and Thredolet.

What is the full form of olet?

The term “olet” in the context of piping fittings does not have a full form; it simply refers to a branch connection fitting used in pipelines. The term “organic light-emitting transistor (OLET)” refers to a different technology used in electronics.

Related Products

- Alloy Steel P22 Buttweld Fitting

- Alloy Steel P11 Buttweld Fitting

- Alloy Steel P5 Buttweld Fitting

- Alloy Steel P9 Buttweld Fitting

- Alloy Steel P91 Buttweld Fitting

- Alloy Steel p12 Buttweld Fitting

- Alloy Steel F22 Forged Fitting

- Alloy Steel F11 Forged Fitting

- Alloy Steel F5 Forged Fitting

- Alloy Steel F9 Forged Fitting

- Alloy Steel F91 Forged Fitting

- Alloy Steel F12 Forged Fitting

- Alloy Steel P22 Plates & Alloy Steel P22 Sheets

- Alloy Steel P11 Plates & Alloy Steel P11 Sheets

- Alloy Steel P5 Plates & Alloy Steel P5 Sheets

- Alloy Steel P9 Plates & Alloy Steel P9 Sheet

- Alloy Steel P22 Round Bars & Alloy Steel P22 Wires

- Alloy Steel P11 Round Bars & Alloy Steel P11 Wires

- Alloy Steel P5 Round Bars & Alloy Steel P5 Wires

- Alloy Steel F9 Round Bars & Alloy Steel F9 Wires

- Alloy Steel F91 Round Bars & Alloy Steel F91 Wires

- Alloy Steel F12 Round Bars & Alloy Steel F12 Wires

- Alloy Steel F22 Flanges

- Alloy Steel F11 Flanges

- Alloy Steel F5 Flanges

- Alloy Steel F9 Flanges

- Alloy Steel F91 Flanges

- Alloy Steel F12 Flanges

- Alloy Steel F22 Olets

- Alloy Steel F11 Olet

-

- Alloy Steel P12 Plates & Alloy Steel P12 Sheets

- Alloy Steel P22 Long Radius Bend

- Alloy Steel P11 Long Radius Bends

- Alloy Steel P5 Long Radius Bends

- Alloy Steel P9 Long Radius Bends

- Alloy Steel P91 Long Radius Bends

- Alloy Steel P12 Long Radius Bends

- Alloy Steel P22 Pipes & Alloy Steel P22 Tubes

- Alloy Steel P11 Pipes & Alloy Steel P11 Tubes

- Alloy Steel P5 Pipes & Alloy Steel P5 Tubes

- Alloy Steel P9 Pipes & Alloy Steel P9 Tubes

- Alloy Steel P91 Pipes & Alloy Steel P91 Tubes

- Alloy Steel P12 Pipes & Alloy Steel P12 Tubes

- Alloy Steel F5 Olets

- Alloy Steel F91 Olets

- Alloy Steel F12 Olets

- Alloy Steel F9 Olets