API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

Table of Content

- API 6A Flanges Manufacturer | API 6A Type 6BX 2000 Flanges

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges Specification

- API 6A Type 6BX 2000 PSI Blind & Weld Neck Flanges

- API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges Pressure Rating

- API 6A Type 6BX 2000 PSI Blind & Weld Flanges Grades

- Applications of API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

- FAQ

API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges Manufacturers & suppliers in UK

High pressure steel flange, forged flanges, API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges Stockholders

API 6A Flanges Manufacturer | API 6A Type 6BX 2000 Flanges

Kalpataru Piping Solutions is a premier supplier of API flanges, including the API 6A Type 6BX 2000 PSI Blind & Weld Neck Flange. We offer a comprehensive range of API 6A flanges, featuring both Type 6B and 6BX with RTJ connections. Our flanges are available in pressure ratings from 2000 PSI (13.8 MPa) up to 20000 PSI (138.0 MPa), engineered to meet international quality standards.

Our API 6A Type 6BX 2000 PSI Blind & Weld Neck Flanges are meticulously crafted to ensure durability and performance in high-pressure applications. These flanges are designed to seal the ends of piping systems or pressure vessel openings, effectively preventing flow. They are ideal for pressure testing and allow easy access for maintenance and inspection.

Kalpataru Piping Solutions provides a wide range of flange dimensions customized to meet the specific needs of our clients. We prioritize customer satisfaction by ensuring that all orders are securely packaged and promptly delivered. Our high-quality API 6A Blind & Weld Neck Flanges comply with ASME, ANSI, and DIN standards, making them suitable for a wide range of industrial applications.

Choose Kalpataru Piping Solutions for your API 6A flange needs and experience exceptional quality and service.

API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges Specification

| Description | Flange | ||||

| Material | Carbon Steel | ASTM A105 ,ASTM A234, ASTM A106, P250GH, P280GHM 16MN, 20MN ,20# | |||

| Alloy Steel | ASTM A182 F1,F5,F7,F9,F11,F12,F22; Hastelloy C276; Inconel 600; Inconel 625; Inconel718; Inconel X750 ; Inconel 800; S31254 ; Monel 400 ; Monel K500 ; 16Mo3 | ||||

| Steels For Low Temperature Service | ASTM A350 LF1, LF2, LF3,LF4,LF6,LF8 | ||||

| Stainless teel | ASTM A240 ,ASTM A182, F304/304H/304L, F316/316H/316L,F321/321H,F347/347H,F348 | ||||

| Duplex Stainless Steel | ASTM A182 F51/F53/F55/F60; UNS S32550(UR52N+);S32750(SAF 2507); S32760(Zeron 100) | ||||

| Standard | ASME/ANSI | Class 150 Class 300 Class 400 Class 600 Class 900 Class1500 Class 2500 | |||

| DIN | 6Bar 10Bar 16Bar 25Bar 40Bar | ||||

| JIS | 5K 10K 16K 20K 30K | ||||

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar | ||||

| AS | Table1 Table2 TableC TableD TableE TableF TableH | ||||

| KS | 5K 10K 16K 20K 30K | ||||

| BS/EN | 6Bar 10Bar 16Bar 25Bar 40Bar 63Bar | ||||

| SABS | 1000-3 1600-3 2500-3 | ||||

| GOST | 6Bar 10Bar 16Bar 25Bar 40Bar 63Bar | ||||

| Size | DN10-DN3600 ; 1/2″~24″ ; 26″~60″ | ||||

| Type | Flat flange; Slip on Flange; Welding neck Flange ; Socket welding;

Lap joint flange ; Threaded flange; Blind flange; Spectacle blind ; Tube sheet |

||||

| Technical | Forged, Steel Plate,Rolling | ||||

| Surfaces | Anti-rust oil ; paint ; hot dip galvanized ; electric galvanized ; Electroless nickel | ||||

| Heat treatment | Normalizing, Tempering, Annealing, Quenching and Tempering, solution treatmentmAging treatment | ||||

| Certificate | We can provide CE PED97/23/EC ; ISO9001:2008 ; American bureau of shipping (ABS) ; det norske veritas (DNV) ; bureau veritas (BV) ;Germany Lloyd’s register (GL) ; the United Kingdom Lloyd’s register (LR) certification. | ||||

| Package | Wooden pallets/Smoked wooden cases, Air Bubble Film,Vacuum packaging, sealing surface with plastic special protective seal, or according to the customers’ requirements | ||||

| Lead Time | Within 30days for quantity of 2000tons | ||||

| Terms | EXW, FOB, CIF, C&F | ||||

| Port of Loading | Shanghai/Tianjin Port | ||||

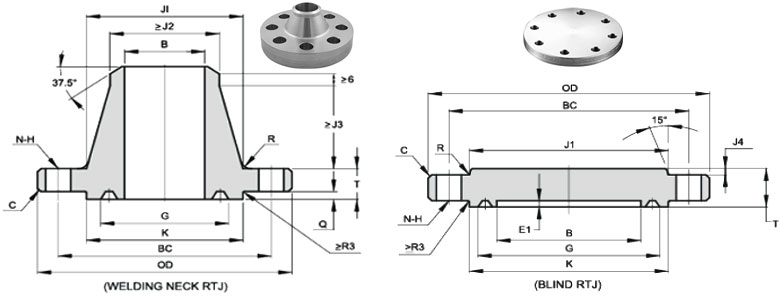

API 6A Type 6BX 2000 PSI Blind & Weld Neck Flanges

|

Size |

OD |

C |

E1 |

G |

K |

T |

J1 |

J4 |

R |

BC |

N |

H |

BX |

|

26 3/4″ |

1040 |

6 |

21.4 |

768.33 |

805 |

126.3 |

835.8 |

9.7 |

16 |

952.5 |

20 |

48 |

167 |

|

30″ |

1120 |

6 |

23 |

862.3 |

908 |

134.2 |

931.9 |

17.5 |

16 |

1039.8 |

32 |

45 |

303 |

API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges Pressure Rating

| API Flange Type | Pressure Rating | Pressure Rating (MPa) | Material | Connection Type | Standards |

| API 6A Type 6BX | 2000 PSI | 13.8 MPa | Carbon Steel, Stainless Steel | RTJ | ASME, ANSI, DIN |

| API 6A Type 6BX | 2000 PSI | 20.7 MPa | Carbon Steel, Stainless Steel | RTJ | ASME, ANSI, DIN |

API 6A Type 6BX 2000 PSI Blind & Weld Flanges Grades

| Grade | Material | Pressure Rating (PSI) | Pressure Rating (MPa) | Connection Type | Standards |

| API 6A Type 6BX | Carbon Steel | 2000 | 13.8 | RTJ | ASME, ANSI, DIN |

| API 6A Type 6BX | Stainless Steel | 2000 | 20.7 | RTJ | ASME, ANSI, DIN |

Applications of API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

API 6A Type 6BX 2000 PSI Blind Flanges from Kalpataru Piping Solutions find wide-ranging applications in high-pressure environments across various industries:

- Oil & Gas: These flanges are crucial for sealing piping systems in upstream, midstream, and downstream operations, ensuring safety and preventing leaks during oil and gas exploration, production, and transportation.

- Pressure Testing: They are essential for conducting pressure tests on pipelines and vessels, detecting leaks, and maintaining system integrity by withstanding high-pressure conditions.

- Petrochemical Plants: API 6A Type 6BX 2000 PSI Blind Flanges play a vital role in managing chemical flow securely in high-pressure environments within petrochemical plants, enhancing safety and reliability in processing operations.

- Refineries: In refineries, these flanges are used to seal pipeline sections during maintenance activities, ensuring safe and efficient operation in high-temperature and high-pressure settings typical of refinery processes.

Marine & Offshore: These flanges are critical for sealing high-pressure systems in harsh marine and offshore environments, where they withstand challenging conditions and contribute to the safety and integrity of marine structures and equipment.

Supply and Exporter of API 6A Type 6B 2000 PSI Weld Neck & Blind Flanges

Taiwan, Mexico, Iran, Namibia, Afghanistan, Netherlands, Nepal, Ireland, Libya, Morocco, Iran, Switzerland, Finland, Slovakia, Pakistan, Australia, Serbia, Angola, China, Philippines, Czech Republic, Belgium, Estonia, Costa Rica, Croatia, Sweden, Venezuela, Colombia, India, Belarus, Jordan, Azerbaijan, Mongolia, Vietnam, Ghana, Iraq, Algeria, Puerto Rico, New Zealand, Singapore, Indonesia, Ukraine, Israel, Mexico, Hong Kong, Bhutan, Germany, Brazil, Plan, Yemen, Malasiya, USA, Cambodia, Laos, Uganda, Tanzania, Sudan, Democratic Republic of Congo, zambia, Ethiopia, Brunei, Madagascar, Niger, Mali, Bangladesh, Bolivia, United States, Ecuador, Lebanon, Italy, South Korea, Denmark, Norway, Sri Lanka, Zimbabwe, Japan, Yemen, Oman, Portugal, Lithuania, Canada, Macau, Bahrain, Austria, Bulgaria, Spain, Kenya, United Kingdom, United Arab Emirates, Kazakhstan, Egypt, Saudi Arabia, Gambia, Argentina, Romania, Tibet, France, Chile, Gabon, South Africa, Trinidad & Tobago,Tunisia, Turkey, Nigeria, Peru, Russia, Chile, Nigeria, Hungary, Qatar, Greece, Malaysia, Kuwait, Poland, Thailand, Poland,Germany, Belgium, Italy, Turkey, Denmark and UK.

FAQ

What is the ASME Code for blind flanges?

The ASME code for blind flanges is ASME B16.5. Blind flanges for pipes and flanged fittings come in various sizes, typically following the ASME B16.5 standard.

What is API 6A type 6B?

API 6A Type 6B refers to weld neck flanges designed according to API (American Petroleum Institute) specifications. These flanges are of the ring joint type and are not intended for face-to-face make-up. The connection make-up bolting force acts on the metallic ring gasket. They are available in sizes ranging from 2-1/16 inches to 21-1/4 inches and pressure ratings of 2000#, 3000#, and 5000#.

What is the 6B flange?

The 6B flange refers to a type of weld neck flange designed according to API (American Petroleum Institute) specifications. These flanges are characterized by their ring joint type and are not intended for face-to-face make-up. The connection make-up bolting force acts on the metallic ring gasket. They are commonly used in high-pressure applications in industries such as oil and gas.