API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges

Table of Content

- API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges Specification

- API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges Dimensions

- API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges Pressure Rating

- API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges Grades

- Advantages of API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges

- Applications of API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges

- FAQ

API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges Manufacturers & suppliers in Europe

High pressure steel flange, forged flanges, API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges suppliers

API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges Suppliers

As a prominent manufacturer specializing in high-pressure steel flanges, Kalpataru Piping Solutions is renowned for its API 6A Type 6BX 3000 PSI Blind Flanges. These forged flanges play a critical role in sealing the end of piping systems or pressure vessel openings, effectively preventing flow.

The design of API 6A flanges is paramount for pressure testing the flow of liquids or gas through pipes or vessels. Furthermore, these API flanges provide convenient access for maintenance or alterations within the line, streamlining operational efficiency. Our comprehensive range of high-quality API 6BX flanges, manufactured to meet ASME, ANSI, and DIN standards, adheres to the highest industry norms in India.

We export API 6A flanges, including API adapter flanges, API blind flanges, and API Series B flanges, at competitive prices. With a precise stock of API 5L Grade B flanges, we ensure timely supply of API flange material at the most competitive prices.

Our API 6A blind flanges are suitable for various applications, offering pressure classes of 720 psi and 960 psi as per API specifications, without alterations to the ASA B16.5 Standard. These flanges utilize the 300 lb. and 400 lb. flanges separately. Designed to perform in temperatures ranging from -75°F to 250°F, the API 6A Type 6B and 6BX flanges offer exceptional reliability and performance.

API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges Specification

| Specification | Details |

| Standard | API 6A |

| Type | 6BX Blind Flange |

| Pressure Rating | 3000 PSI |

| Material | Carbon Steel, Stainless Steel, Alloy Steel |

| Size Range | 1 13/16″ to 21 1/4″ |

| Connection | Ring-Type Joint (RTJ) |

| Face Finish | Smooth Finish, Serrated Finish |

| Coating | Anti-corrosion Coating, as required |

| Dimensions | As per API 6A |

| Temperature Rating | -50°F to 350°F (depending on material) |

| Usage | Oil and Gas, Petrochemical, Offshore Drilling |

| Testing | Hydrostatic Test, Nondestructive Examination |

| Certification | API Monogram, Material Test Report (MTR) |

| Marking | As per API 6A requirements |

| Customization | Available upon request |

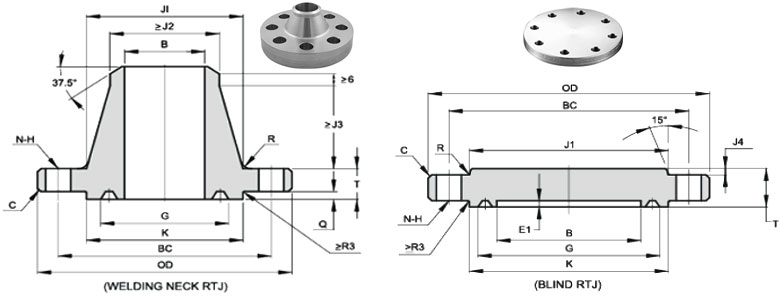

API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges Dimensions

| Size | B | OD | C | K | P | E | T | Q | X | BC | N | H | LN | HL | JL | R/RX |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

2 1/16″ |

53.2 |

215 |

3 |

124 |

95.25 |

7.9 |

46.1 |

38.1 |

105 |

165.1 |

8 |

26 |

110 |

60.3 |

50 |

24 |

|

2 9/16″ |

65.9 |

245 |

3 |

137 |

107.95 |

7.9 |

49.3 |

41.3 |

124 |

190.5 |

8 |

29 |

113 |

73 |

59.7 |

27 |

|

3 1/8″ |

81.8 |

240 |

3 |

156 |

123.83 |

7.9 |

46.1 |

38.1 |

127 |

190.5 |

8 |

26 |

110 |

88.9 |

74.4 |

31 |

|

4 1/16″ |

108.7 |

290 |

3 |

181 |

149.23 |

7.9 |

52.4 |

44.4 |

159 |

235 |

8 |

32 |

122 |

114.3 |

98 |

37 |

|

5 1/8″ |

131 |

350 |

3 |

216 |

180.98 |

7.9 |

58.8 |

50.8 |

191 |

279.4 |

8 |

35 |

135 |

141.3 |

122.9 |

41 |

|

7 1/16″ |

181.8 |

380 |

6 |

241 |

211.15 |

7.9 |

63.5 |

55.6 |

235 |

317.5 |

12 |

32 |

148 |

168.3 |

147.1 |

45 |

|

9″ |

229.4 |

470 |

6 |

308 |

269.88 |

7.9 |

71.5 |

63.5 |

299 |

393.7 |

12 |

39 |

170 |

219.1 |

189.7 |

49 |

|

11″ |

280.2 |

545 |

6 |

362 |

323.85 |

7.9 |

77.8 |

69.9 |

368 |

469.9 |

16 |

39 |

192 |

273 |

237.2 |

53 |

|

13 5/8″ |

346.9 |

610 |

6 |

419 |

381 |

7.9 |

87.4 |

79.4 |

419 |

533.4 |

20 |

39 |

– |

– |

– |

57 |

|

16 3/4″ |

426.2 |

705 |

6 |

524 |

469.9 |

11 |

100 |

88.9 |

508 |

616 |

20 |

45 |

– |

– |

– |

66 |

|

20 3/4″ |

527.8 |

855 |

6 |

648 |

584.2 |

13 |

121 |

108 |

622 |

749.3 |

20 |

54 |

– |

– |

– |

74 |

API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges Pressure Rating

| Nominal Size (inches) | Pressure Rating (PSI) | Outside Diameter (inches) | Number of Bolts | Bolt Circle Diameter (inches) | Bolt Hole Diameter (inches) | Minimum Thickness (inches) |

| 1 13/16 | 3000 | 7.06 | 4 | 5.75 | 0.81 | 1.88 |

| 2 1/16 | 3000 | 7.88 | 4 | 6.50 | 0.81 | 2.00 |

| 2 9/16 | 3000 | 8.75 | 4 | 7.38 | 0.81 | 2.25 |

| 3 1/8 | 3000 | 9.75 | 4 | 8.38 | 0.88 | 2.50 |

| 4 1/16 | 3000 | 11.50 | 4 | 9.88 | 0.88 | 2.75 |

| 5 1/8 | 3000 | 13.75 | 4 | 12.00 | 0.88 | 3.13 |

| 7 1/16 | 3000 | 17.75 | 8 | 15.00 | 1.00 | 3.88 |

| 9 | 3000 | 21.75 | 8 | 18.38 | 1.00 | 4.75 |

API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges Grades

| Grade | Material Composition | Applications |

| AA | Carbon Steel | Suitable for general applications where low-temperature service is required. |

| BB | Low Alloy Steel | Ideal for moderate temperature and pressure conditions, often used in wellheads and manifolds. |

| CC | Corrosion-Resistant Alloy (CRA) | Used in environments where corrosion resistance is critical, such as offshore and subsea operations. |

| DD | Stainless Steel | Suitable for high-temperature and high-pressure environments, commonly used in sour service conditions. |

| EE | Nickel Alloy | Used in extreme temperature and corrosive environments, offering superior resistance to cracking and pitting. |

| FF | Low-Temperature Carbon Steel | Designed for low-temperature applications, ensuring ductility and toughness under cold conditions. |

| HH | High Strength Low Alloy (HSLA) Steel | Ideal for high-pressure and high-stress applications, providing enhanced strength and durability. |

Advantages of API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges

Leak Prevention: These flanges provide an effective seal for pipe or valve ends, preventing leaks of fluid or gas and enhancing system safety.

Easy Maintenance: Blind flanges can be easily removed for inspection or repairs, ensuring that the system remains in optimal condition with minimal downtime.

Flexibility: Available in a variety of materials and configurations, these flanges are highly adaptable for diverse applications across industries such as oil, gas, petrochemical, and offshore drilling.

Cost-Effectiveness: Compared to other types of flanges, blind flanges offer a cost-effective solution for many industrial uses, providing reliable sealing performance at a lower cost.

Applications of API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges

Oil & Gas: These flanges are crucial for capping off pipelines and valves, allowing for isolation during maintenance, pressure testing, or future expansions in the oil and gas industry.

Chemical Processing: Similar to their role in oil and gas, blind flanges are used in chemical processing to isolate sections for maintenance, cleaning, or process changes while ensuring system integrity.

Power Generation: These flanges play a vital role in power generation by isolating sections of piping for maintenance or equipment upgrades within power plants, contributing to the efficient and safe operation of power generation facilities.

Food & Beverage: Blind flanges are essential in the food and beverage industry for maintaining hygiene. They seal off sections for cleaning or equipment changes, ensuring the integrity of food and beverage processing facilities.

Pharmaceutical: In pharmaceutical production, maintaining sterility is paramount. Blind flanges enable isolation for cleaning or equipment maintenance, contributing to the production of safe and high-quality pharmaceutical products.

Supply and Exporter of API 6A Type 6B 3000 PSI Weld Neck & Blind Flanges

Taiwan, Mexico, Iran, Namibia, Afghanistan, Netherlands, Nepal, Ireland, Libya, Morocco, Iran, Switzerland, Finland, Slovakia, Pakistan, Australia, Serbia, Angola, China, Philippines, Czech Republic, Belgium, Estonia, Costa Rica, Croatia, Sweden, Venezuela, Colombia, India, Belarus, Jordan, Azerbaijan, Mongolia, Vietnam, Ghana, Iraq, Algeria, Puerto Rico, New Zealand, Singapore, Indonesia, Ukraine, Israel, Mexico, Hong Kong, Bhutan, Germany, Brazil, Plan, Yemen, Malasiya, USA, Cambodia, Laos, Uganda, Tanzania, Sudan, Democratic Republic of Congo, zambia, Ethiopia, Brunei, Madagascar, Niger, Mali, Bangladesh, Bolivia, United States, Ecuador, Lebanon, Italy, South Korea, Denmark, Norway, Sri Lanka, Zimbabwe, Japan, Yemen, Oman, Portugal, Lithuania, Canada, Macau, Bahrain, Austria, Bulgaria, Spain, Kenya, United Kingdom, United Arab Emirates, Kazakhstan, Egypt, Saudi Arabia, Gambia, Argentina, Romania, Tibet, France, Chile, Gabon, South Africa, Trinidad & Tobago,Tunisia, Turkey, Nigeria, Peru, Russia, Chile, Nigeria, Hungary, Qatar, Greece, Malaysia, Kuwait, Poland, Thailand, Poland,Germany, Belgium, Italy, Turkey, Denmark and UK.

FAQ

What is the pressure rating for API 3000 flange?

API flange designations, like API 6A Type 6BX 3000 PSI, don’t directly indicate pressure ratings. However, the “3000” in their name typically suggests a pressure rating of 3,000 PSI.

What is the pressure rating of a 3000 class valve?

A 3000 class valve typically has a pressure rating of 3000 psi, making it suitable for servicing water, oil, and gaseous fluids under a maximum working pressure of 3000 psi.

What is the ANSI equivalent of API 3000?

The ANSI equivalent of API 3000 is typically found in ANSI flanges with class ratings such as 600 to 900 and 1500. These ANSI flanges are dimensionally equivalent to API 3000 in most sizes, up to ANSI 12 inches (API 13 5/8 inches). However, ANSI flanges, being made from lower yield strength carbon steel, are rated to lower working pressures compared to API flanges.