API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges

Home

Table of Content

- API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges supplier

- API 6A Type 6BX 5000 PSI flanges

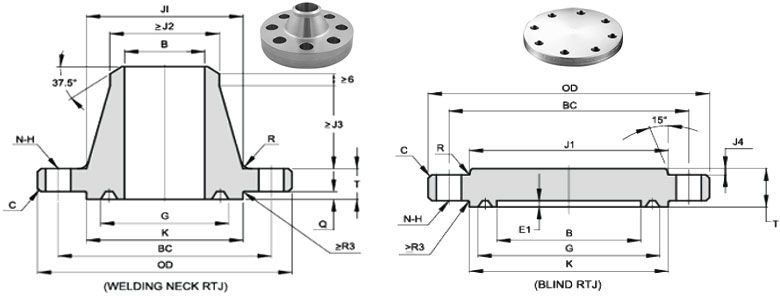

- API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges Dimensions

- API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges Specification

- API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges Mechanical Properties

- API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges Equivalent Grade

- Chemical Composition of API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges

- Supply and Exporter of API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges

- FAQ

API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges Manufacturers & suppliers in Europe .

High pressure steel flange, forged flanges, API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges Stockholders.

API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges supplier

Kalpataru Piping Solutions stands out as a premier manufacturer and supplier of API 6A Type 6B 5000 PSI Blind & Weld Neck Flanges, meticulously engineered for demanding high-pressure environments, whether hot or cold. These robust steel flanges are meticulously welded into systems, facilitating easy radiographic inspection of the weld area. This design not only enhances system integrity but also minimizes turbulence and erosion within pipelines, ensuring prolonged service life and reducing stress concentration points.

Fabricated to match pipe diameters precisely, our API 6A Type 6B 5000 PSI Blind & Weld Neck Flanges guarantee a seamless fit, translating to optimal performance in critical applications. Whether you require flanges for oil and gas, petrochemical, or offshore drilling applications, our comprehensive range of products is tailored to meet your unique needs. Contact us today for more information and discover how we can address your specific requirements with precision and expertise.

API 6A Type 6BX 5000 PSI flanges

API 6B 5000 PSI flanges are robust and high-pressure flange systems designed for demanding industrial applications. Manufactured by Kalpataru Piping Solutions, these flanges are expertly crafted to withstand extreme pressures and temperatures commonly encountered in industries such as oil exploration, subsea wellhead operations, and high-pressure drilling projects. Kalpataru Piping Solutions ensures the quality and reliability of these flanges through rigorous testing and certifications, including Raw Materials Certificate and 100% Radiography Test Report. This ensures that the flanges meet industry standards and specifications, providing peace of mind to customers regarding their performance and durability in critical applications. With resistance to both cryogenic and high temperatures, these flanges offer exceptional reliability and safety in challenging industrial environments.API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges Dimensions

|

Size |

B |

OD |

C |

K |

P |

E |

T |

Q |

X |

BC |

N |

H |

LN |

HL |

JL |

R/RX |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

2 1/16″ |

53.2 |

215 |

3 |

124 |

95.25 |

7.9 |

46.1 |

38.1 |

105 |

165.1 |

8 |

26 |

110 |

60.3 |

43.7 |

24 |

|

2 9/16″ |

65.9 |

245 |

3 |

137 |

107.95 |

7.9 |

49.3 |

41.3 |

124 |

190.5 |

8 |

29 |

113 |

73 |

54.9 |

27 |

|

3 1/8″ |

81.8 |

265 |

3 |

168 |

136.53 |

7.9 |

55.6 |

47.7 |

133 |

203.2 |

8 |

32 |

125 |

88.9 |

67.5 |

35 |

|

4 1/16″ |

108.7 |

310 |

3 |

194 |

161.93 |

7.9 |

62 |

54 |

162 |

241.3 |

8 |

35 |

132 |

114.3 |

88.1 |

39 |

|

5 1/8″ |

131 |

375 |

3 |

229 |

193.68 |

7.9 |

81 |

73.1 |

197 |

292.1 |

8 |

42 |

164 |

141.3 |

110.3 |

44 |

|

7 1/16″ |

181.8 |

395 |

6 |

248 |

211.15 |

9.7 |

92.1 |

82.6 |

229 |

317.5 |

12 |

39 |

181 |

168.3 |

132.6 |

46 |

|

9″ |

229.4 |

485 |

6 |

318 |

269.88 |

11 |

103 |

92.1 |

292 |

393.7 |

12 |

45 |

224 |

219.1 |

173.8 |

50 |

|

11″ |

280.2 |

585 |

6 |

371 |

323.85 |

11 |

119 |

108 |

368 |

482.6 |

12 |

51 |

265 |

273.1 |

216.7 |

54 |

Note:

- RING NUMBER R or RX,

- C should be the max value

- Tolerance and Ring Gasket according to API 6A-20TH

API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges Specification

| Dimensions | API 6A Type 6B Welding Neck 5,000 PSI. |

| Size | 2-1/16”, 2-9/16”, 3-1/8”, 4-1/16”, 5-1/8”. |

| Pressure | 5K, 5,000 PSI |

| Delivery Condition | Annealed, Normalized, Stress Relieved, Quenched & Tempered. |

| Product Specification Level (PSL) | PSL 1, PSL 2, PSL 3. |

| Supplementary Requirement | NACE MR0175 / MR0103 ISO 3183 / NACE TM0284 YS – MIN 85,000, UTS – 1,10,000 WITHSTANDING 15,000 PRESSURE. |

API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges Mechanical Properties

| Property | Value |

| Density | High |

| Melting Point | Typically above 1500°C |

| Yield Strength | High, 0.2% Offset |

| Tensile Strength | High |

| Elongation | Moderate to High |

API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges Equivalent Grade

|

Equivalent Grades |

Material |

|

ASTM A105 |

Carbon Steel |

|

ASTM A182 F316 |

Stainless Steel |

|

ASTM A182 F22 |

Alloy Steel |

|

ASTM A350 LF2 |

Low-Temperature Steel |

|

ASTM A694 F60 |

High-Yield Carbon Steel |

|

ASTM A182 F51 |

Duplex Steel |

Chemical Composition of API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges

|

Element |

Composition (%) |

|

Carbon (C) |

0.28 – 0.33 |

|

Manganese (Mn) |

0.40 – 0.60 |

|

Phosphorus (P) |

0.035 max |

|

Sulfur (S) |

0.040 max |

|

Silicon (Si) |

0.15 – 0.35 |

|

Chromium (Cr) |

0.80 – 1.10 |

|

Molybdenum (Mo) |

0.15 – 0.25 |

|

Nickel (Ni) |

0.40 – 0.70 |

|

Copper (Cu) |

0.35 max |

Supply and Exporter of API 6A Type 6B 5000 PSI Weld Neck & Blind Flanges

Taiwan, Mexico, Iran, Namibia, Afghanistan, Netherlands, Nepal, Ireland, Libya, Morocco, Iran, Switzerland, Finland, Slovakia, Pakistan, Australia, Serbia, Angola, China, Philippines, Czech Republic, Belgium, Estonia, Costa Rica, Croatia, Sweden, Venezuela, Colombia, India, Belarus, Jordan, Azerbaijan, Mongolia, Vietnam, Ghana, Iraq, Algeria, Puerto Rico, New Zealand, Singapore, Indonesia, Ukraine, Israel, Mexico, Hong Kong, Bhutan, Germany, Brazil, Plan, Yemen, Malasiya, USA, Cambodia, Laos, Uganda, Tanzania, Sudan, Democratic Republic of Congo, zambia, Ethiopia, Brunei, Madagascar, Niger, Mali, Bangladesh, Bolivia, United States, Ecuador, Lebanon, Italy, South Korea, Denmark, Norway, Sri Lanka, Zimbabwe, Japan, Yemen, Oman, Portugal, Lithuania, Canada, Macau, Bahrain, Austria, Bulgaria, Spain, Kenya, United Kingdom, United Arab Emirates, Kazakhstan, Egypt, Saudi Arabia, Gambia, Argentina, Romania, Tibet, France, Chile, Gabon, South Africa, Trinidad & Tobago,Tunisia, Turkey, Nigeria, Peru, Russia, Chile, Nigeria, Hungary, Qatar, Greece, Malaysia, Kuwait, Poland, Thailand, Poland,Germany, Belgium, Italy, Turkey, Denmark and UK.

FAQ

What is the pressure rating for API 5000 flange?

The pressure rating for an API 5000 flange typically corresponds to a pressure of 5000 pounds per square inch (psi). These flanges are designed to withstand high-pressure environments and are commonly used in applications where elevated pressures are encountered, such as in oil and gas processing facilities.

What is API 6A type 6B?

API 6A Type 6B refers to weld neck flanges that adhere to the API standard 6A. These flanges, designed for high-pressure applications, are of the ring joint type, utilizing metallic ring gaskets for sealing. Unlike other flanges, they don’t facilitate face-to-face make-up; instead, the bolting force during connection reacts on the metallic ring gasket. Available in sizes from 2-1/16″ to 21-1/4″, they boast pressure ratings of 2000#, 3000#, and 5000#.

What are the material classes in API 6A?

In API 6A, the material classes are denoted as AA, BB, CC, DD, EE, FF, and HH. Additionally, there are product specification levels 1, 2, 3, and 4 (PSL 1, 2, 3, 4) along with performance requirements 1 and 2.

OTHER ALLOY STEEL

AVAILABLE MATERIAL

Related Products

-

- Alloy Steel P11 Buttweld Fitting

- Alloy Steel P5 Buttweld Fitting

- Alloy Steel P9 Buttweld Fitting

- Alloy Steel P91 Buttweld Fitting

- Alloy Steel p12 Buttweld Fitting

- Alloy Steel F22 Forged Fitting

- Alloy Steel F11 Forged Fitting

- Alloy Steel F5 Forged Fitting

- Alloy Steel F9 Forged Fitting

- Alloy Steel F91 Forged Fitting

- Alloy Steel F12 Forged Fitting

- Alloy Steel P22 Plates & Alloy Steel P22 Sheets

- Alloy Steel P11 Plates & Alloy Steel P11 Sheets

- Alloy Steel P5 Plates & Alloy Steel P5 Sheets

- Alloy Steel P9 Plates & Alloy Steel P9 Sheet

- Alloy Steel P91 Plates & Alloy Steel P91 Sheets

- Alloy Steel P12 Plates & Alloy Steel P12 Sheets

- Alloy Steel P22 Long Radius Bend

- Alloy Steel P11 Long Radius Bends

- Alloy Steel P5 Long Radius Bends

- Alloy Steel P9 Long Radius Bends

- Alloy Steel P91 Long Radius Bends

- Alloy Steel P12 Long Radius Bends

- Alloy Steel P22 Pipes & Alloy Steel P22 Tubes

- Alloy Steel P11 Pipes & Alloy Steel P11 Tubes

- Alloy Steel P5 Pipes & Alloy Steel P5 Tubes

- Alloy Steel P9 Pipes & Alloy Steel P9 Tubes

- Alloy Steel P91 Pipes & Alloy Steel P91 Tubes

- Alloy Steel P12 Pipes & Alloy Steel P12 Tubes

- Alloy Steel F5 Olets

- Alloy Steel F91 Olets

- Alloy Steel F12 Olets

- Alloy Steel F9 Olet

- Alloy Steel P22 Round Bars & Alloy Steel P22 Wires

- Alloy Steel P11 Round Bars & Alloy Steel P11 Wires

- Alloy Steel P5 Round Bars & Alloy Steel P5 Wires

- Alloy Steel F9 Round Bars & Alloy Steel F9 Wires

- Alloy Steel F91 Round Bars & Alloy Steel F91 Wires

- Alloy Steel F12 Round Bars & Alloy Steel F12 Wires

- Alloy Steel F22 Flanges

- Alloy Steel F11 Flanges

- Alloy Steel F5 Flanges

- Alloy Steel F9 Flanges

- Alloy Steel F91 Flanges

- Alloy Steel F12 Flanges

- Alloy Steel F22 Olets

- Alloy Steel F11 Olet