API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges

Home

Table of Content

- API 6A Flanges Manufacturer | API 10000 Blind & Weld Neck Flanges Supplier

- API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges Dimensions

- API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges Specification

- API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges Pressure Rating

- API 6A Type 6BX 10000 Blind & Weld Neck Flanges Measurement

- Applications API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges

- Supply and Exporter of API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges

- FAQ

API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges Manufacturers & suppliers in Europe.

High pressure steel flange, forged flanges, API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges Stockholders.

API 6A Flanges Manufacturer | API 10000 Blind & Weld Neck Flanges Supplier

Kalpataru Piping Solutions is a leading manufacturer and supplier of top-quality API 10000 flanges. These flanges adhere to the stringent standards set by the American Petroleum Institute (API), specifically API 6A, and are divided into PSL 1 and PSL 2 levels, with PSL 2 flanges undergoing more rigorous testing for enhanced reliability in demanding applications.

Our API 10000 psi flanges are engineered to meet stringent criteria for qualification, temperature resilience, design integrity, and rigorous testing. This ensures they deliver unparalleled quality and safety. We cater to various industries including petroleum, petrochemical, natural gas, and offshore drilling. As a trusted manufacturer of API 6A Type 6BX Flanges, we utilize premium materials such as carbon steel, alloy steel, stainless steel, duplex and super duplex stainless steel, Inconel, and Hastelloy. These flanges are heat-treated for superior strength, boasting a minimum yield strength of 75,000 psi, making them perfect for high-pressure environments.

Available in sizes ranging from ½ inch to 24 inches, our API 6A flanges are designed as ring-type joint flanges conforming to API 6A standards. Whether you require API 6A Blind Flanges to securely close a pipeline or flanges suited for various pressure levels, Kalpataru Piping Solutions offers dependable and high-quality products at competitive prices.

Contact us for your API 10000 flanges requirements and experience exceptional manufacturing quality and service.

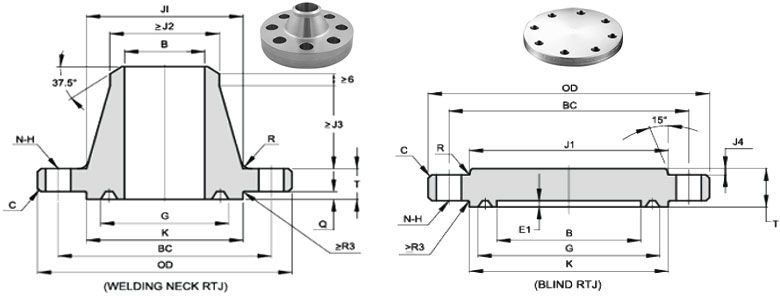

API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges Dimensions

| Size | B | OD | C | E1 | Q | G | K | T | J1 | J2 | J3 | J4 | R | BC | N | H | BX |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

1 13/16″ |

46.8 |

185 |

3 |

– |

5.56 |

77.77 |

105 |

42.1 |

88.9 |

65.1 |

48.5 |

– |

10 |

146.1 |

8 |

23 |

151 |

|

2 1/16″ |

53.2 |

200 |

3 |

– |

5.95 |

86.23 |

111 |

44.1 |

100 |

74.7 |

51.6 |

– |

10 |

158.8 |

8 |

23 |

152 |

|

2 9/16″ |

65.9 |

230 |

3 |

– |

6.75 |

102.77 |

132 |

51.2 |

120.7 |

92.1 |

57.2 |

– |

10 |

184.2 |

8 |

26 |

153 |

|

3 1/16″ |

78.6 |

270 |

3 |

– |

7.54 |

119 |

152 |

58.4 |

142.1 |

110.2 |

63.5 |

– |

10 |

215.9 |

8 |

29 |

154 |

|

4 1/16″ |

104 |

315 |

3 |

– |

8.33 |

150.62 |

185 |

70.3 |

182.6 |

146.1 |

73.1 |

– |

10 |

258.8 |

8 |

32 |

155 |

|

5 1/8″ |

131 |

360 |

3 |

9.5 |

9.53 |

176.66 |

221 |

79.4 |

223.8 |

182.6 |

81 |

6.4 |

10 |

300 |

12 |

32 |

169 |

|

7 1/16″ |

180.2 |

480 |

6 |

11.1 |

11.11 |

241.83 |

302 |

103.2 |

301.6 |

254 |

95.3 |

9.7 |

16 |

403.2 |

12 |

42 |

156 |

|

9 “ |

229.4 |

550 |

6 |

12.7 |

12.7 |

299.06 |

359 |

123.9 |

374.7 |

327.1 |

93.7 |

9.7 |

16 |

476.3 |

16 |

42 |

157 |

|

11″ |

280.2 |

655 |

6 |

14.3 |

14.29 |

357.23 |

429 |

141.3 |

450.9 |

400.1 |

103.2 |

14.2 |

16 |

565.2 |

16 |

48 |

158 |

|

13 5/8″ |

346.9 |

770 |

6 |

15.9 |

15.88 |

432.64 |

518 |

168.3 |

552.5 |

495.3 |

114.3 |

17.5 |

16 |

673.1 |

20 |

51 |

159 |

|

16 3/4″ |

426.2 |

870 |

6 |

8.3 |

8.33 |

478.33 |

576 |

168.3 |

655.6 |

601.7 |

76.2 |

30.2 |

19 |

776.3 |

24 |

51 |

162 |

|

18 3/4″ |

477 |

1040 |

6 |

18.3 |

18.26 |

577.9 |

697 |

223.1 |

752.5 |

674.7 |

155.6 |

25.4 |

16 |

925.5 |

24 |

61 |

164 |

|

21 1/4″ |

540.5 |

1145 |

6 |

19.1 |

19.05 |

647.88 |

781 |

241.3 |

847.7 |

762 |

165.1 |

31.8 |

21 |

1022.4 |

24 |

67 |

166 |

Note:

- RING NUMBER R or RX,

- C should be the max value

- Tolerance and Ring Gasket according to API 6A-20TH

API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges Specification

| Specifications | API 6A Flanges |

|---|---|

| Size Ranges | From 1/2 inch (i.e. 15 NB) upto 48 inch (i.e. 1200NB) |

| Standards | ASME | BS | DIN | ANSI | GOST | EN Flange |

| JIS Standards | 5 K, 10K, 16K, 20 K, 30K, 40K, 63 K |

| Flange Face Type | FF, RF, LMF, SMF, RTJ, LJF. |

| Other Pressure Classes | Cl 150, Class 300, Cl. 400, 600, Class 900, Cl 1500 and 2500 |

| Production Process | Machined, Heat Treated, Forged |

| UNI/ DIN / EN Standard | 6Bar, 10 Bar, 16Bar, 25 Bar, 40Bar |

API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges Pressure Rating

| NPS | Working Pressure Of API Flanges In (PSI) | Outside Diameter For (O.D.) | No. of (B.H.) Bolt Holes | Diameter Of (B.H.) Bolt Holes | Bolts Length | API Flanges Ring Gasket |

| 1-13/16″ | 10,000 | 7-3/8″ | 8 | 3/4″ | 5-1/4″ | BX-151 |

| 1-13/16″ | 15,000 | 8-3/16″ | 8 | 7/8″ | 6″ | BX-151 |

| 1-13/16″ | 20,000 | 10-1/8″ | 8 | 1″ | 7-3/4″ | BX-151 |

| 2-1/16″ | 2,000 | 6-1/2″ | 8 | 5/8″ | 5/8″ | R-23 |

| 2-1/16″ | 3,000/5,000 | 8-1/2″ | 8 | 7/8″ | 7/8″ | R-24 |

| 2-1/16″ | 10,000 | 7-7/8″ | 8 | 3/4″ | 3/4″ | BX-152 |

| 2-1/16″ | 15,000 | 8-3/4″ | 8 | 7/8″ | 7/8″ | BX-152 |

| 2-1/16″ | 20,000 | 11-5/16″ | 8 | 1-1/8″ | 1-1/8″ | BX-152 |

| 2-9/16″ | 2,000 | 7-1/2″ | 8 | 3/4″ | 5-1/4″ | R-26 |

| 2-9/16″ | 3,000/5,000 | 9-5/8″ | 8 | 1″ | 7″ | R-27 |

| 2-9/16″ | 10,000 | 9-1/8″ | 8 | 7/8″ | 6-1/4″ | BX-153 |

| 2-9/16″ | 15,000 | 10″ | 8 | 1″ | 7″ | BX-153 |

| 2-9/16″ | 20,000 | 12-13/16″ | 8 | 1-1/4″ | 9-1/2″ | BX-153 |

| 3-1/8″ | 2,000 | 8-1/4″ | 8 | 3/4″ | 5-1/2″ | R-31 |

| 3-1/8″ | 3,000 | 9-1/2″ | 8 | 7/8″ | 6-1/4″ | R-31 |

| 3-1/8″ | 5,000 | 10-1/2″ | 8 | 1-1/8″ | 7-3/4″ | R-35 |

| 3-1/16″ | 10,000 | 10-5/8″ | 8 | 1″ | 7-1/4″ | BX-154 |

| 3-1/16″ | 15,000 | 11-5/16″ | 8 | 1-1/8″ | 8″ | BX-154 |

| 3-1/16″ | 20,000 | 14-1/16″ | 8 | 1-3/8″ | 10-3/4″ | BX-154 |

| 4-1/16″ | 2,000 | 10-3/4″ | 8 | 7/8″ | 6-1/4″ | R-37 |

| 4-1/16″ | 3,000 | 11-1/2″ | 8 | 1-1/8″ | 7-1/2″ | R-37 |

| 4-1/16″ | 5,000 | 12-1/4″ | 8 | 1-1/8″ | 8-3/8″ | BX-155 |

| 4-1/16″ | 20,000 | 17-9/16″ | 8 | 1-3/4″ | 12-3/4″ | BX-155 |

| 5-1/8″ | 5,000 | 14-3/4″ | 8 | 1-1/2″ | 10-3/4″ | R-44 |

| 7-1/16″ | 2,000 | 14″ | 12 | 1″ | 7-1/2″ | R-45 |

| 7-1/16″ | 3,000 | 15″ | 12 | 1-1/8″ | 8-1/2″ | R-45 |

| 7-1/16″ | 5,000 | 15-1/2″ | 12 | 1-3/8″ | 11-1/4″ | R-46 |

| 7-1/16″ | 10,000 | 18-7/8″ | 12 | 1-1/2″ | 11-3/4″ | BX-156 |

| 7-1/16″ | 15,000 | 19-7/8″ | 16 | 1-1/2″ | 13″ | BX-156 |

| 7-1/16″ | 20,000 | 24-13/16″ | 16 | 2″ | 17-3/4″ | BX-156 |

| 9″ | 2,000 | 16-1/2″ | 12 | 1-1/8″ | 8-1/2″ | R-49 |

| 9″ | 3,000 | 18-1/2″ | 12 | 1-3/8″ | 9-1/2″ | R-49 |

| 9″ | 5,000″ | 19″ | 12 | 1-5/8″ | 12-1/2″ | R-50 |

| 9″ | 10,000 | 21-3/4″ | 16 | 1-1/2″ | 13-1/4″ | BX-157 |

| 9″ | 15,000 | 25-1/2″ | 16 | 1-7/8″ | 16″ | BX-157 |

| 11″ | 2,000 | 20″ | 16 | 1-1/4″ | 9-1/4″ | R-53 |

| 11″ | 3,000 | 21-1/2″ | 16 | 1-3/8″ | 10″ | R-53 |

| 11″ | 5,000 | 23″ | 12 | 1-7/8″ | 14-1/4″ | R-54 |

| 11″ | 10,000 | 25-3/4″ | 16 | 1-3/4″ | 15-3/8″ | BX-158 |

| 11″ | 15,000 | 32″ | 20 | 2″ | 19-1/2″ | BX-158 |

| 13-5/8″ | 2,000 | 22″ | 20 | 1-1/4″ | 9-1/2″ | R-57 |

| 13-5/8″ | 3,000 | 24″ | 20 | 1-3/8″ | 10-3/4″ | R-57 |

| 13-5/8″ | 5,000 | 26-1/2″ | 16 | 1-5/8″ | 12-3/4″ | BX-160 |

| 13-5/8″ | 10,000 | 30-1/4″ | 20 | 1-7/8″ | 17-3/4″ | BX-159 |

| 13-5/8″ | 15,000 | 34-7/8″ | 20 | 2-1/4″ | 21″ | BX-159 |

| 16-3/4″ | 2,000 | 27″ | 20 | 1-1/2″ | 10-3/4″ | R-65 |

| 16-3/4″ | 3,000 | 27-3/4″ | 20 | 1-5/8″ | 12-1/4″ | R-66 |

| 16-3/4″ | 5,000 | 30-3/8″ | 16 | 1-78″ | 14-3/4″ | BX-162 |

| 16-3/4″ | 10,000 | 34-5/16″ | 24 | 1-7/8″ | 17-3/4″ | BX-162 |

| 18-3/4″ | 5,000 | 35-5/8″ | 20 | 2″ | 18″ | BX-163 |

| 16-3/4″ | 10,000 | 40-15/16″ | 24 | 2-1/4″ | 23″ | BX-164 |

| 20-3/4″ | 3,000 | 33-3/4″ | 20 | 2″ | 15-1/4″ | R-74 |

| 21-1/4″ | 2,000 | 32″ | 24 | 1-5/8″ | 12-1/2″ | R-73 |

| 21-1/4″ | 5,000 | 39″ | 24 | 2″ | 19″ | BX-165 |

| 21-1/4″ | 10,000 | 45″ | 24 | 2-1/2″ | 24-3/4″ | BX-166 |

| 26-3/4″ | 2,000 | 41″ | 20 | 1-3/4″ | 14-1/4″ | BX-167 |

| 21-1/4″ | 3,000 | 43-3/8″ | 24 | 2″ | 17-1/2″ | BX-168 |

API 6A Type 6BX 10000 Blind & Weld Neck Flanges Measurement

Key measurements for API 6A Type 6BX 10000 Blind & Weld Neck Flanges:- O (Outside Diameter): Total diameter from edge to edge.

- T (Thread Length): Minimum length of threads for a secure connection.

- Q (Bolt Circle Diameter): Minimum diameter through the centers of bolt holes.

- Y (Length Through Hub): Distance from flange face to hub end.

- R (Raised Face Diameter): Diameter of the raised sealing surface.

- X (Hub Diameter at Base): Diameter of the hub at its base.

- C (Flange Thickness): Thickness of the flange body.

Applications API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges

API 6A Type 6BX 10000 PSI Weld Neck Flanges are essential in various industrial piping applications due to their ability to withstand high pressure and ensure secure connections. Key applications include:

- Oil and Gas Industry: These flanges are integral in oil and gas piping systems, efficiently transporting crude oil, natural gas, and other petroleum products.

- Chemical Processing Industry: Used extensively in chemical processing plants, weld neck flanges handle the transportation of various chemicals and materials safely.

- Water Treatment Industry: Weld neck flanges are critical in water treatment plants, facilitating the movement of water and other fluids through the system.

- Power Generation Industry: In power generation plants, these flanges are utilized to transport steam, gas, and other fluids, ensuring efficient and safe operations.

These applications demonstrate the versatility and reliability of API 6A Type 6BX 10000 PSI Weld Neck Flanges in handling high-pressure conditions across diverse industries.

Supply and Exporter of API 6A Type 6BX 10000 PSI Blind & Weld Neck Flanges

Taiwan, Mexico, Iran, Namibia, Afghanistan, Netherlands, Nepal, Ireland, Libya, Morocco, Iran, Switzerland, Finland, Slovakia, Pakistan, Australia, Serbia, Angola, China, Philippines, Czech Republic, Belgium, Estonia, Costa Rica, Croatia, Sweden, Venezuela, Colombia, India, Belarus, Jordan, Azerbaijan, Mongolia, Vietnam, Ghana, Iraq, Algeria, Puerto Rico, New Zealand, Singapore, Indonesia, Ukraine, Israel, Mexico, Hong Kong, Bhutan, Germany, Brazil, Plan, Yemen, Malasiya, USA, Cambodia, Laos, Uganda, Tanzania, Sudan, Democratic Republic of Congo, zambia, Ethiopia, Brunei, Madagascar, Niger, Mali, Bangladesh, Bolivia, United States, Ecuador, Lebanon, Italy, South Korea, Denmark, Norway, Sri Lanka, Zimbabwe, Japan, Yemen, Oman, Portugal, Lithuania, Canada, Macau, Bahrain, Austria, Bulgaria, Spain, Kenya, United Kingdom, United Arab Emirates, Kazakhstan, Egypt, Saudi Arabia, Gambia, Argentina, Romania, Tibet, France, Chile, Gabon, South Africa, Trinidad & Tobago,Tunisia, Turkey, Nigeria, Peru, Russia, Chile, Nigeria, Hungary, Qatar, Greece, Malaysia, Kuwait, Poland, Thailand, Poland,Germany, Belgium, Italy, Turkey, Denmark and UK.FAQ

What is a 10000 psi flange rating?

A 10000 psi flange rating, as specified in API 6A, indicates that the flange is designed to withstand pressures up to 10,000 psi. These high-pressure flanges are used in applications requiring robust performance under extreme pressure conditions, with overall pressure capacities ranging from 2,000 psi to 20,000 psi.

What is the pressure rating of a 10000 flange?

The pressure rating of a 10K flange, in the context of JIS (Japanese Industrial Standards), is typically 10 kg/cm² (approximately 142 psi). However, it’s important to note that “10K” can also refer to flanges designed for much higher pressures in other standards, such as API 6A, where a 10K flange would denote a pressure rating of 10,000 psi.

What is a weld neck flange used for?

Weld neck flanges are used in applications where conditions are severe and critical, including high pressure, wide fluctuations in temperature and pressure, high temperature, volatile and hazardous fluids, and sub-zero temperatures. Their design ensures a strong, leak-proof connection, making them ideal for demanding environments.

OTHER ALLOY STEEL

AVAILABLE MATERIAL

Related Products

-

- Alloy Steel P11 Buttweld Fitting

- Alloy Steel P5 Buttweld Fitting

- Alloy Steel P9 Buttweld Fitting

- Alloy Steel P91 Buttweld Fitting

- Alloy Steel p12 Buttweld Fitting

- Alloy Steel F22 Forged Fitting

- Alloy Steel F11 Forged Fitting

- Alloy Steel F5 Forged Fitting

- Alloy Steel F9 Forged Fitting

- Alloy Steel F91 Forged Fitting

- Alloy Steel F12 Forged Fitting

- Alloy Steel P22 Plates & Alloy Steel P22 Sheets

- Alloy Steel P11 Plates & Alloy Steel P11 Sheets

- Alloy Steel P5 Plates & Alloy Steel P5 Sheets

- Alloy Steel P9 Plates & Alloy Steel P9 Sheet

- Alloy Steel P91 Plates & Alloy Steel P91 Sheets

- Alloy Steel P12 Plates & Alloy Steel P12 Sheets

- Alloy Steel P22 Long Radius Bend

- Alloy Steel P11 Long Radius Bends

- Alloy Steel P5 Long Radius Bends

- Alloy Steel P9 Long Radius Bends

- Alloy Steel P91 Long Radius Bends

- Alloy Steel P12 Long Radius Bends

- Alloy Steel P22 Pipes & Alloy Steel P22 Tubes

- Alloy Steel P11 Pipes & Alloy Steel P11 Tubes

- Alloy Steel P5 Pipes & Alloy Steel P5 Tubes

- Alloy Steel P9 Pipes & Alloy Steel P9 Tubes

- Alloy Steel P91 Pipes & Alloy Steel P91 Tubes

- Alloy Steel P12 Pipes & Alloy Steel P12 Tubes

- Alloy Steel F5 Olets

- Alloy Steel F91 Olets

- Alloy Steel F12 Olets

- Alloy Steel F9 Olet

- Alloy Steel P22 Round Bars & Alloy Steel P22 Wires

- Alloy Steel P11 Round Bars & Alloy Steel P11 Wires

- Alloy Steel P5 Round Bars & Alloy Steel P5 Wires

- Alloy Steel F9 Round Bars & Alloy Steel F9 Wires

- Alloy Steel F91 Round Bars & Alloy Steel F91 Wires

- Alloy Steel F12 Round Bars & Alloy Steel F12 Wires

- Alloy Steel F22 Flanges

- Alloy Steel F11 Flanges

- Alloy Steel F5 Flanges

- Alloy Steel F9 Flanges

- Alloy Steel F91 Flanges

- Alloy Steel F12 Flanges

- Alloy Steel F22 Olets

- Alloy Steel F11 Olet