API 6A Type 6BX 5000 PSI Blind & Weld Neck Flanges

Table of Content

- API 6A Flanges Suppliers | API 5000 Blind & Weld Neck Flanges

- What are API 6B 5000 PSI Flanges?

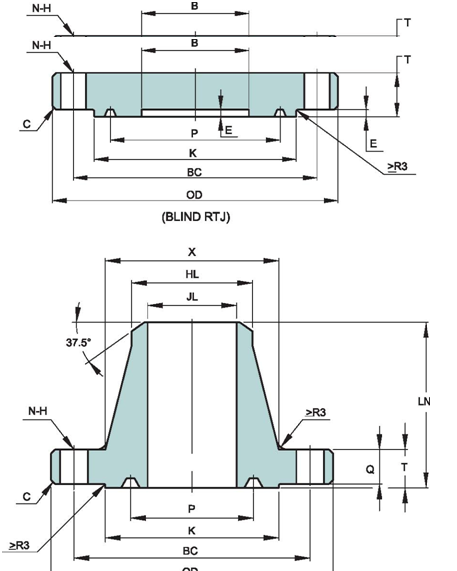

- API 6A Type 6BX 5000 PSI Blind & Weld Neck Flanges Dimension

- Specification of API 6A Type 6BX 5000 PSI Blind & Weld Neck Flanges

- Chemical Composition of API 6A Type 6BX 5000 PSI Weld Neck & Blind Flanges

- API 6A Type 6BX 5000 PSI Weld Neck & Blind Flanges Mechanical Properties

- API 6A Type 6BX 5000 PSI Blind & Weld Neck Flanges Equivalent Grade

- API 6A Type 6BX 5000 PSI Blind & Weld Neck Flanges Application

- FAQ

API 6A TYPE 6B 5000 PSI Blind Flanges | API 5000 PSI Flanges | API 6A TYPE 6B 5000 PSI Weld Neck Flanges | API 6A 5000 PSI WNRF Flange | WNFF API 5000 PSI | API 5000 PSI Weld Neck Flange | API 6A TYPE 6B 5000 PSI Weld Neck Dimensions| Weld Neck Flanges Manufacturer | WNRF Flanges | Weld Neck Flanges

API 6A Flanges Suppliers | API 5000 Blind & Weld Neck Flanges

Kalpataru Piping Solutions specializes in manufacturing and supplying API 6A Type 6B 5000 PSI Blind & Weld Neck Flanges, designed specifically for high-pressure applications in various environmental conditions. These steel flanges are welded around pipelines, allowing easy inspection of welds using radiography. Their unique design minimizes turbulence and erosion within pipelines, ensuring durability and reducing stress concentration over the long term.

Our API 6A Type 6B 5000 PSI Blind & Weld Neck Flanges are precision-machined to fit seamlessly with different pipe diameters, ensuring optimal performance in critical applications. Whether for hot or cold environments, our flanges are engineered to meet stringent quality standards. Contact us today for more information or specific requirements.

What are API 6B 5000 PSI Flanges?

Kalpataru Piping Solutions specializes in manufacturing API 6A Type 6BX 5000 PSI flanges, designed for demanding high-pressure applications. These flanges undergo extensive testing and certifications to ensure top quality, including Raw Materials Certificates and 100% Radiography Test Reports. They are engineered to withstand extreme temperatures, from cryogenic conditions to high heat, making them well-suited for industrial use in applications such as Subsea Wellhead systems, Oil Exploration, and high-pressure drilling projects.

API 6A Type 6BX 5000 PSI Blind & Weld Neck Flanges Dimension

|

Size |

O |

C |

K |

P |

E |

X |

BC |

N |

H |

Y |

A |

B2 |

Ring Number R or RX |

|

2 1/16″ |

215 |

46.1 |

124 |

95.25 |

7.9 |

104.8 |

165.1 |

8 |

26 |

109.6 |

60.3 |

43.7 |

24 |

|

2 9/16″ |

245 |

49.3 |

137 |

107.95 |

7.9 |

123.8 |

190.5 |

8 |

29 |

112.7 |

73 |

54.9 |

27 |

|

3 1/8″ |

265 |

55.6 |

168 |

136.53 |

7.9 |

133.3 |

203.2 |

8 |

32 |

125.4 |

88.9 |

67.5 |

35 |

|

4 1/16″ |

310 |

62 |

194 |

161.93 |

7.9 |

161.9 |

241.3 |

8 |

35 |

131.8 |

114.3 |

88.1 |

39 |

|

5 1/8″ |

375 |

81 |

229 |

193.68 |

7.9 |

196.8 |

292.1 |

8 |

42 |

163.5 |

141.3 |

110.3 |

44 |

|

7 1/16″ |

395 |

92.1 |

248 |

211.15 |

9.7 |

228.6 |

317.5 |

12 |

39 |

181 |

168.3 |

132.6 |

46 |

|

9″ |

485 |

103.2 |

318 |

269.88 |

11.2 |

292.1 |

393.7 |

12 |

45 |

223.8 |

219.1 |

173.8 |

50 |

|

11″ |

585 |

119.1 |

371 |

323.85 |

11.2 |

368.3 |

482.6 |

12 |

51 |

265.1 |

273 |

216.7 |

54 |

Specification of API 6A Type 6BX 5000 PSI Blind & Weld Neck Flanges

|

Dimensions |

API 6A Type 6B Welding Neck 5,000 PSI. |

|

Size |

2-1/16”, 2-9/16”, 3-1/8”, 4-1/16”, 5-1/8”. |

|

Pressure |

5K, 5,000 PSI |

|

Delivery Condition |

Annealed, Normalized, Stress Relieved, Quenched & Tempered. |

|

Product Specification Level (PSL) |

PSL 1, PSL 2, PSL 3. |

|

Supplementary Requirement |

NACE MR0175 / MR0103 ISO 3183 / NACE TM0284 YS – MIN 85,000, UTS – 1,10,000 WITHSTANDING 15,000 PRESSURE. |

Chemical Composition of API 6A Type 6BX 5000 PSI Weld Neck & Blind Flanges

|

Element |

Composition (%) |

|

Carbon (C) |

0.28 – 0.33 |

|

Manganese (Mn) |

0.40 – 0.60 |

|

Phosphorus (P) |

0.035 max |

|

Sulfur (S) |

0.040 max |

|

Silicon (Si) |

0.15 – 0.35 |

|

Chromium (Cr) |

0.80 – 1.10 |

|

Molybdenum (Mo) |

0.15 – 0.25 |

|

Nickel (Ni) |

0.40 – 0.70 |

|

Copper (Cu) |

0.35 max |

API 6A Type 6BX 5000 PSI Weld Neck & Blind Flanges Mechanical Properties

| Property | Value |

| Density | High |

| Melting Point | Typically above 1500°C |

| Yield Strength | High, 0.2% Offset |

| Tensile Strength | High |

| Elongation | Moderate to High |

API 6A Type 6BX 5000 PSI Blind & Weld Neck Flanges Equivalent Grade

|

Equivalent Grades |

Material |

|

ASTM A105 |

Carbon Steel |

|

ASTM A182 F316 |

Stainless Steel |

|

ASTM A182 F22 |

Alloy Steel |

|

ASTM A350 LF2 |

Low-Temperature Steel |

|

ASTM A694 F60 |

High-Yield Carbon Steel |

|

ASTM A182 F51 |

Duplex Steel |

API 6A Type 6BX 5000 PSI Blind & Weld Neck Flanges Application

API 6A Type 6BX 5000 PSI blind and weld neck flanges find critical applications across several industries due to their robust design and high-pressure capabilities:

- Oil and Gas Industry- These flanges are integral in oil and gas operations, particularly in offshore drilling and subsea installations. They seal wellheads, manifolds, and other critical connections, ensuring safe and reliable operation under high pressures.

- Petrochemical Plants- API 6A Type 6BX flanges are used extensively in petrochemical facilities for connecting pipelines and equipment subjected to high-pressure environments. They maintain system integrity during processing and transportation of chemicals and gas.

- Power Generation- In power plants, these flanges are employed to seal high-pressure steam and gas lines. They facilitate efficient energy production by securely connecting critical components and allowing for maintenance and inspection as needed.

- Subsea Applications- Due to their resilience against harsh environmental conditions and corrosion resistance, API 6BX flanges are preferred in subsea installations. They ensure leak-free connections in underwater pipelines and equipment used in offshore oil exploration and production.

- Industrial Applications- Beyond traditional energy sectors, these flanges are used in various industrial applications requiring high-pressure handling capabilities. This includes chemical processing, water treatment plants, and other heavy-duty industrial processes.

API 6A Type 6BX 5000 PSI flanges are chosen for their reliability, durability, and adherence to stringent industry standards, making them indispensable in critical operations where safety and performance are paramount.

Supply and Exporter of API 6A TYPE 6B 3000 PSI Weld Neck Flanges

Taiwan, Mexico, Iran, Namibia, Afghanistan, Netherlands, Nepal, Ireland, Libya, Morocco, Iran, Switzerland, Finland, Slovakia, Pakistan, Australia, Serbia, Angola, China, Philippines, Czech Republic, Belgium, Estonia, Costa Rica, Croatia, Sweden, Venezuela, Colombia, India, Belarus, Jordan, Azerbaijan, Mongolia, Vietnam, Ghana, Iraq, Algeria, Puerto Rico, New Zealand, Singapore, Indonesia, Ukraine, Israel, Mexico, Hong Kong, Bhutan, Germany, Brazil, Plan, Yemen, Malasiya, USA, Cambodia, Laos, Uganda, Tanzania, Sudan, Democratic Republic of Congo, zambia, Ethiopia, Brunei, Madagascar, Niger, Mali, Bangladesh, Bolivia, United States, Ecuador, Lebanon, Italy, South Korea, Denmark, Norway, Sri Lanka, Zimbabwe, Japan, Yemen, Oman, Portugal, Lithuania, Canada, Macau, Bahrain, Austria, Bulgaria, Spain, Kenya, United Kingdom, United Arab Emirates, Kazakhstan, Egypt, Saudi Arabia, Gambia, Argentina, Romania, Tibet, France, Chile, Gabon, South Africa, Trinidad & Tobago,Tunisia, Turkey, Nigeria, Peru, Russia, Chile, Nigeria, Hungary, Qatar, Greece, Malaysia, Kuwait, Poland, Thailand, Poland,Germany, Belgium, Italy, Turkey, Denmark and UK.

FAQ

What does API stand for in flanges?

API stands for the American Petroleum Institute in the context of flanges. The API establishes standards for equipment used in the oil and gas industry, including specifications for flanges used in various applications.

What is the ANSI equivalent of API 5000?

The ANSI equivalent of API 5000 flanges is typically ANSI Class 3000. This classification denotes the pressure rating of the flange, indicating it can withstand pressures up to 3000 pounds per square inch (PSI).

What is API 6A type 6BX?

API 6A Type 6BX flanges are specifically designed ring joint flanges used in high-pressure oil and gas applications. These flanges are employed in pipelines to block off the flow of liquids or gas during maintenance or repair operations. They are known for their robust construction and ability to withstand high pressures, typically up to 20,000 PSI.