Inconel Products

Inconel Manufacturer, Inconel Suppliers in India, Inconel Tube Suppliers, Inconel Material Price, Inconel Tubing Suppliers, Inconel 625 Suppliers, Inconel 718 Suppliers.

Leading Manufacturer of Inconel flanges, Inconel tubes, Inconel pipe, Inconel Sheets and Plates, Inconel Pipe Fittings, Inconel Forged Fittings and Inconel Fasteners

Kalpataru Piping Solutions is a leading manufacturer and supplier of Inconel products, including grades 600, 601, 625, and 718. We offer a wide range of items such as flanges, fittings, pipes, tubes, and fasteners in various sizes and specifications. Our products are exported to numerous international markets, including the USA, the Arab world, and Europe.

About Inconel Products

Inconel refers to a series of high-performance nickel-chromium superalloys designed to maintain strength and resist oxidation at elevated temperatures. These alloys excel in environments prone to stress-corrosion cracking, caustic corrosion, and corrosion from ultra-pure water. While each Inconel variant has specific characteristics, they are predominantly used in the chemical industry due to their durability and resistance to harsh conditions.

Types of Inconel Product

Inconel Material Specification

| Inconel Alloy | Properties | Applications | Available Forms |

|---|---|---|---|

| Inconel 600 | Solid solution strengthened | – | – |

| Inconel 601 | – | – | – |

| Inconel 625 | Acid resistant, good weldability. The LCF version is typically used in bellows. | Ideal for hardware and components in the power, aerospace, and chemical processing industries. | Sheet, plate, bar, and forgings |

| Inconel 718 | Gamma double prime strengthened with good weldability. | Preferred material for cryogenic storage tanks, turbines, downhole shafts, and wellhead parts. | Sheet, plate, and bar |

| Inconel X750 | – | Commonly used for gas turbine components, including blades, seals, and rotors. | – |

| Inconel 907 | – | – | – |

| Inconel 909 | – | – | – |

| Inconel 706 | – | – | – |

| Inconel 617 | – | – | – |

| Inconel 751 | Increased aluminum content for improved rupture strength in the 1600°F range. | – | – |

| Inconel 792 | Increased aluminum content for improved high-temperature corrosion properties. | Used especially in gas turbines. | – |

| Inconel 939 | Gamma prime strengthened to increase weldability. | – | – |

| Inconel 188 | Readily fabricated for commercial gas turbine and aerospace applications. | – | Sheet, plate, and bar |

| Inconel 690 | Low cobalt content for nuclear applications, and low resistivity. | – | – |

| Inconel 713C | Precipitation hardenable nickel-chromium base cast alloy. | – | – |

| Inconel 230 | – | Mainly used by the power, aerospace, chemical processing, and industrial heating industries. | Sheet and plate |

Composition of Inconel

| Inconel | Element, proportion by mass (%) | ||||||||||||||

| Ni | Cr | Fe | Mo | Nb & Ta | Co | Mn | Cu | Al | Ti | Si | C | S | P | B | |

| 600[11] | ≥72.0[a] | 14.0–17.0 | 6.0–10.0 | — | ≤1.0 | ≤0.5 | ≤0.5 | ≤0.15 | ≤0.015 | ||||||

| 617[18] | 44.2–61.0 | 20.0–24.0 | ≤3.0 | 8.0–10.0 | 10.0–15.0 | ≤0.5 | ≤0.5 | 0.8–1.5 | ≤0.6 | ≤0.5 | 0.05–0.15 | ≤0.015 | ≤0.015 | ≤0.006 | |

| 625[19] | ≥58.0 | 20.0–23.0 | ≤5.0 | 8.0–10.0 | 3.15–4.15 | ≤1.0 | ≤0.5 | ≤0.4 | ≤0.4 | ≤0.5 | ≤0.1 | ≤0.015 | ≤0.015 | ||

| 690[20] | ≥58 | 27–31 | 7–11 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.05 | ≤0.015 | |||||||

| Nuclear grade 690[20] | ≥58 | 28–31 | 7–11 | ≤0.10 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.04 | ≤0.015 | ||||||

| 718[2] | 50.0–55.0 | 17.0–21.0 | Balance | 2.8–3.3 | 4.75–5.5 | ≤1.0 | ≤0.35 | ≤0.3 | 0.2–0.8 | 0.65–1.15 | ≤0.35 | ≤0.08 | ≤0.015 | ≤0.015 | ≤0.006 |

| X-750[21] | ≥70.0 | 14.0–17.0 | 5.0–9.0 | 0.7–1.2 | ≤1.0 | ≤1.0 | ≤0.5 | 0.4–1.0 | 2.25–2 | ||||||

Inconel Mechanical Properties

| Material | Form and Condition | Tensile Strength | Yield | Elongationgation % | Hardness, Rockwell | ||

|---|---|---|---|---|---|---|---|

| Inconel Alloy 600 rod and bar | Cold drawn Annealed | 80-100 | 550-690 | 25-50 | 170-345 | 55-35 | 65-85B |

| Inconel Alloy 600 Plate | Hot rolled Annealed | 80-100 | 550-725 | 30-50 | 205-345 | 55-35 | 65-85B |

| Inconel Alloy 600 Sheet | Cold Rolled Annealed | 80-100 | 550-690 | 30-45 | 205-310 | 55-35 | 88B max |

| Inconel Alloy 600 Tube and Pipe | Cold Drawn Annealed | 80-100 | 550-690 | 25-50 | 170-345 | 55-35 | 88B max |

| Inconel Alloy 600 Wire | Cold Drawn Annealed | 80-120 | 550-830 | 35-75 | 240-520 | 45-20 | – |

| Inconel Alloy 600 Wire | Cold Drawn No 1 Temper | 105-135 | 725-930 | 70-105 | 480-725 | 35-15 | – |

| Inconel Alloy 600 Wire | Spring Temper | 170-220 | 1170-1520 | 150-210 | 1035-1450 | 5-2 | – |

| Inconel Alloy 625 Bar | Annealed | 120 | 827 | 60 | 414 | 30 | ≤ 287 HB |

| Inconel Alloy 625 Sheet | Annealed | 120 | 827 | 60 | 414 | 30 | 145-240 |

| Inconel Alloy 625 Tube Seamless and Welded |

Annealed | 120 | 827 | 60 | 414 | 35 | – |

Inconel Uses and Applications

Inconel alloys are valued for their ability to withstand extreme temperatures and maintain strength under high-heat conditions. This makes them ideal for various demanding applications:

- Jet Engines: Used in engine components due to their resistance to high temperatures and oxidation.

- Marine Applications: Ideal for parts exposed to harsh sea environments, including offshore oil rigs and ship components.

- Aerospace Industries: Employed in various aerospace components where high strength and resistance to high temperatures are crucial.

- Heat Treat Baskets: Suitable for applications in heat treatment processes where high temperatures are prevalent.

We Export To Inconel Products

New Zealand, Ukraine, Brazil, Azerbaijan, Angola, United Kingdom, Philippines, Oman, France, Algeria, Macau, Sri Lanka, Tibet, Norway, Mexico, Venezuela, Denmark, Russia, Bhutan, Estonia, Austria, Vietnam, Argentina, Turkey, Greece, Romania, Bahrain, Bangladesh, Afghanistan, Italy, Poland, Zimbabwe, Thailand, India, Kenya, Ecuador, Puerto Rico, Nepal, Malaysia, Bulgaria, Libya, Slovakia, Chile, Serbia, Australia, Poland, Iran, Costa Rica, Peru, South Korea, Iraq, Iran, Indonesia, Spain, Trinidad & Tobago,Tunisia, Qatar, Japan, Canada, Taiwan, Yemen, Mongolia, Czech Republic, Israel, Ghana, Egypt, Nigeria, Saudi Arabia, United Arab Emirates, Namibia, Hungary, South Africa, Hong Kong, Croatia, Colombia, Lebanon, Nigeria, Portugal, Finland, Pakistan, Jordan, Sweden, Belgium, Gambia, Lithuania, United States, Chile, Bolivia, Germany, Singapore, Ireland, Gabon, Kuwait, Switzerland, Mexico, Belarus, Kazakhstan, Morocco, China, Netherlands, Germany, Belgium, Italy, Turkey, Denmark and UK.

FAQ

What is the chemical composition of Inconel?

Inconel alloys are high-performance superalloys primarily composed of nickel and chromium, with additional elements like iron, cobalt, manganese, copper, niobium, and tantalum, tailored to specific alloy grades for enhanced properties and performance.

What is the component of Inconel?

Inconel is a nickel-chromium-based superalloy designed for extreme environments. Its key components include nickel and chromium, with additional elements like iron, cobalt, manganese, copper, niobium, and tantalum, depending on the specific Inconel grade. This composition provides excellent oxidation and corrosion resistance, as well as high strength at elevated temperatures.

What is the raw material of Inconel?

The raw materials of Inconel primarily include nickel and chromium. These elements form the base of the alloy, while additional elements such as iron, cobalt, manganese, copper, niobium, and tantalum are used in various combinations depending on the specific Inconel grade.

Related Products

- Inconel 718 Forged Fittings

- Inconel EN NiCr15Fe Forged Fittings

- Inconel 601 Forged Fittings

- Inconel 625 Forged Fittings

- Inconel 718 Buttweld Fittings

- Inconel 600 Buttweld Fittings

- Inconel 601 Buttweld Fittings

- Inconel 625 Buttweld Fittings

- Inconel 718 Plates & Inconel 718 Sheets

- Inconel 600 Plate & Inconel 600 Sheet

- Inconel 601 Sheets & Inconel 601 Plates

- Inconel 625 Plates & Inconel 625 Sheets

- Inconel 718 Round Bars & Inconel 718 Wires

- Inconel 600 Round bars & Inconel 600 Wires

- Inconel 601 Round Bars & Inconel 601 Wires

- Inconel 625 Round Bars & Inconel 625 Wires

- Inconel 625 Pipes & Inconel 625 Tubes

- Inconel 718 Pipes & Inconel 718 Tubes

- Inconel 718 Compression Tube Fittings

- Inconel 600 Compression Tube Fittings

- Inconel 601 Compression Tube Fittings

- Inconel 625 Compression Tube Fittings

- Inconel 718 Instrumentation Valves

- Inconel 600 Instrumentation Valves

- Inconel 625 Instrumentation Valves

- Inconel 718 Wire Mesh

- Inconel 600 Wire mesh

- Inconel 601 Wire Mesh

- Inconel 625 Wire Mesh

- Inconel 718 Filler Wire

- Inconel 600 Filler Wire

- Inconel 601 Filler WIre

- Inconel 625 Filler Wire

- Inconel 601 Long Radius Bend

- Inconel 718 Long Radius Bends

- Inconel EN NiCr15Fe Long Radius Bend

- Inconel 625 Long Radius Bend

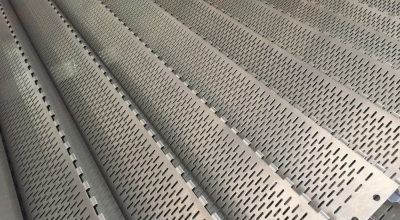

- Inconel 718 Perforated Sheets

- Inconel 600 Perforated Sheet

- Inconel 601 Perforated Sheets

- Inconel 625 Perforated Sheets

- Inconel 718 shims

- Inconel 600 Shims

- Inconel 601 Shims

- Inconel 625 Shims

- Inconel 718 Flanges

- Inconel 600 Flanges

- Inconel 601 Flanges

- Inconel 625 Flanges

- Inconel 718 olets

- Inconel 600 Olets

- Inconel 601 Olets

- Inconel 625 Olets

- Inconel 718 Fasteners

- Inconel 600 Fasteners

- Inconel 601 Fasteners

- Inconel 625 Fasteners

- Inconel 600 Pipes and Inconel 600 Tubes

- Inconel 601 Pipes & Inconel 601 Tubes