Stainless Steel 304/304L/304H Wire Mesh Suppliers

Table of Content

- Stainless Steel 304 / 304L / 304H Wire Mesh Specification

- SS 304/304L/304H Wire Mesh Equivalent Grades

- ASME SA 276 SS 304 / 304L / 304H Wire Mesh Chemical Composition

- Stainless Steel 304/304L/304H Wire Mesh Mechanical Properties

- 304 / 304L / 304H Stainless Steel Wire Mesh Dimensions

- SS 304/304L/304H Wire Application Industries

- FAQ

SS 304 Wire, 304L Stainless Steel Wire, 304H SS Coil Wire, Stainless Steel 304 Welding Wire, ASTM A580 304L Stainless Steel Wire, Stainless Steel 1.4301 Filler Wires, SS 304L Electrode Wires, UNS S30409 Flux Cored Wire, Stainless Steel 304 Wires Suppliers and Exporters in Europe.

ASTM A164 Stainless Steel 304 Welding Wire Mesh, Stockist of Stainless Steel 304L Netting Wire Mesh Supplier, Stainless Steel UNS S31700 Fencing Wire Mesh & DIN 1.4306 SS Wire Mesh Manufacturer in India.

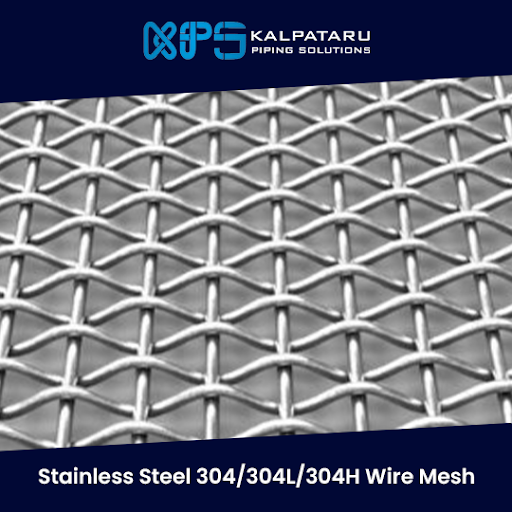

Kalpataru Piping Solutions is a leading manufacturer and supplier of SS 304, 304L, and 304H Wire Mesh. These wire meshes are popular for their resistance to intergranular corrosion when exposed to temperatures between 425°C and 850°C. However, it’s important to note that Stainless Steel 304 Wire Mesh is not ideal for use as a consumable in high-temperature arcs, as titanium does not transfer well in such conditions.

Stainless Steel 304L Coil Wire Mesh is preferred for applications up to 900°C, offering a balance of high strength, resistance to scaling, and stability, along with protection against corrosion in aqueous environments. The Stainless Steel 304H Wire Mesh, with its higher carbon content, is specifically designed to provide enhanced strength at high temperatures, making it a suitable choice for demanding applications.

Like other austenitic stainless steels, SS 304 has excellent forming capabilities and can be easily brake-formed or roll-formed. It also features outstanding properties where post-weld annealing is not necessary. The SS 304L Welding Electrode is a titanium-stabilized, heat-resistant alloy commonly used in environments with temperatures ranging from 1000°F to 1600°F. SS 304H Wire Mesh is primarily used in applications with continuous or intermittent service temperatures between 800°F and 1500°F, within the carbide precipitation range

Stainless Steel 304 / 304L / 304H Wire Mesh Specification

| Specifications | ASTM A276, A580 / ASME SA276, SA580 |

| Standards | DIN, ASTM, ASME, BS and all International Standards |

| Dimensions | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Diameter | Outside Diameter in the range of 4mm to 500mm |

| Width | 1m to 48″ |

| Hex Bars | 18mm – 57mm (11/16″ to 2-3/4″) |

| Square Bars | 18mm – 47mm (11/16″ to 1-3/4″) |

| Flat Bars | 1/2” to 10” in the thickness range of 2mm to 150mm, |

| Wire Length | Max 12000 mm |

| Wire Mesh Length | 30m to 100″ |

| Wire Diameter | 5.5 – 400 mm |

| Finish | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Length | 1 to 6 Meters, Custom Cut Lengths |

| Form | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging, Wire Mesh, Hexagonal Wiremesh, Welding Wiremesh, Netting Wiremesh, Woven Wiremesh, Spring Steel wire mesh, Fencing Wiremesh Etc |

SS 304/304L/304H Wire Mesh Equivalent Grades

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | BS | GOST |

| SS 304 | S30400 | 1.4301 | Z7CN18‐09 | X5CrNi18-10 | SUS 304 | 304S31 | 08Х18Н10 |

| SS 304L | S30403 | 1.4306 / 1.4307 | Z3CN18‐10 | X2CrNi18-9 / X2CrNi19-11 | SUS 304L | 3304S11 | 03Х18Н11 |

| SS 304H | S30409 | 1.4948 | – | – | – | – | – |

ASME SA 276 SS 304 / 304L / 304H Wire Mesh Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 304 | 0.08 max | 2.0 max | 0.75 max | 0.045 max | 0.030 max | 18 – 20 | – | 8 – 11 | – |

| SS 304L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 13 | – |

| SS 304H | 0.10 max | 2.0 max | 0.75 max | 0.045 max | 0.03 max | 18 – 20 | – | 8 – 10.5 | – |

Stainless Steel 304/304L/304H Wire Mesh Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 304 | 515 | 205 | 40 | 92 | 201 |

| 304L | 485 | 170 | 40 | 92 | 201 |

| 304H | 485 | 205 | 40 | 92 | 201 |

304 / 304L / 304H Stainless Steel Wire Mesh Dimensions

| Diameter or Width (mm) |

Weight per meter | Sectional Area | Perimeter | |||

| Square (kg) |

Round (kg) |

Square (cm²) |

Round (cm²) |

Square (cm) |

Round (cm) |

|

| 5.0 | 0.20 | 0.15 | 0.25 | 0.20 | 2.0 | 1.57 |

| 5.5 | 0.24 | 0.19 | 0.30 | 0.24 | 2.2 | 1.78 |

| 6.0 | 0.28 | 0.22 | 0.36 | 0.28 | 2.4 | 1.88 |

| 7.0 | 0.38 | 0.30 | 0.49 | 0.38 | 2.8 | 2.20 |

| 8.0 | 0.50 | 0.39 | 0.64 | 0.50 | 3.2 | 2.51 |

| 9.0 | 0.64 | 0.50 | 0.81 | 0.64 | 3.6 | 2.83 |

| 10 | 0.73 | 0.63 | 1.00 | 0.79 | 4.0 | 3.14 |

| 11 | 0.95 | 0.75 | 1.21 | 0.95 | 4.4 | 3.46 |

| 12 | 1.13 | 0.89 | 1.44 | 1.13 | 4.8 | 3.77 |

| 14 | 1.54 | 1.21 | 1.96 | 1.54 | 5.6 | 4.40 |

| 16 | 2.01 | 1.58 | 2.56 | 2.01 | 6.4 | 5.03 |

| 18 | 2.54 | 2.00 | 3.24 | 2.54 | 7.2 | 5.65 |

| 20 | 3.14 | 2.47 | 4.00 | 3.14 | 8.0 | 6.28 |

| 22 | 3.80 | 2.98 | 4.84 | 3.80 | 8.8 | 6.91 |

| 25 | 4.91 | 3.85 | 6.25 | 4.91 | 10.0 | 7.85 |

| 28 | 6.15 | 4.83 | 7.84 | 6.16 | 11.2 | 8.80 |

| 32 | 8.04 | 6.31 | 10.24 | 8.04 | 12.8 | 10.05 |

| 36 | 10.17 | 7.99 | 12.96 | 10.18 | 14.4 | 11.31 |

| 40 | 12.56 | 9.86 | 16.00 | 12.57 | 16.0 | 12.57 |

| 45 | 15.90 | 12.49 | 20.25 | 15.90 | 18.0 | 14.14 |

| 50 | 19.62 | 15.41 | 25.00 | 19.64 | 20.0 | 15.71 |

| 56 | 24.62 | 19.34 | 31.36 | 24.63 | 22.4 | 17.59 |

| 63 | 31.16 | 24.47 | 36.69 | 31.17 | 25.2 | 19.79 |

| 71 | 39.57 | 31.08 | 50.41 | 39.59 | 28.4 | 22.31 |

| 80 | 50.24 | 39.46 | 64.00 | 50.27 | 32.0 | 25.13 |

SS 304/304L/304H Wire Application Industries

- Off-Shore Oil Drilling Companies

- Power Generation

- Petrochemicals

- Gas Processing

- Specialty Chemicals

- Pharmaceuticals

- Pharmaceutical Equipment

- Chemical Equipment

- Sea Water Equipment

- Heat Exchangers

- Condensers

- Pulp and Paper Industry

These industries rely on SS 304, 304L, and 304H wire mesh due to its excellent corrosion resistance, durability, and ability to withstand harsh environments and high temperatures.

We Export To Stainless Steel Pipes & Tubes

New Zealand, Ukraine, Brazil, Azerbaijan, Angola, United Kingdom, Philippines, Oman, France, Algeria, Macau, Sri Lanka, Tibet, Norway, Mexico, Venezuela, Denmark, Russia, Bhutan, Estonia, Austria, Vietnam, Argentina, Turkey, Greece, Romania, Bahrain, Bangladesh, Afghanistan, Italy, Poland, Zimbabwe, Thailand, India, Kenya, Ecuador, Puerto Rico, Nepal, Malaysia, Bulgaria, Libya, Slovakia, Chile, Serbia, Australia, Poland, Iran, Costa Rica, Peru, South Korea, Iraq, Iran, Indonesia, Spain, Trinidad & Tobago,Tunisia, Qatar, Japan, Canada, Taiwan, Yemen, Mongolia, Czech Republic, Israel, Ghana, Egypt, Nigeria, Saudi Arabia, United Arab Emirates, Namibia, Hungary, South Africa, Hong Kong, Croatia, Colombia, Lebanon, Nigeria, Portugal, Finland, Pakistan, Jordan, Sweden, Belgium, Gambia, Lithuania, United States, Chile, Bolivia, Germany, Singapore, Ireland, Gabon, Kuwait, Switzerland, Mexico, Belarus, Kazakhstan, Morocco, China, Netherlands, Germany, Belgium, Italy, Turkey, Denmark and UK.

FAQ

What is 304 stainless steel mesh?

304 stainless steel mesh is made from austenitic stainless steel, which is a non-magnetic alloy with a solid solution of carbon in a nonmagnetic form of iron. This type of mesh is known for its excellent corrosion resistance, durability, and versatility. It has poor thermal and electrical conductivity, making it suitable for various applications where these properties are desired.

What is stainless steel grade 304 and 304L?

Grade 304 and 304L stainless steel are both austenitic alloys with at least 18% chromium and 8% nickel. The primary difference between them lies in their carbon content: Type 304 has a maximum carbon content of 0.07%, while Type 304L has a lower maximum carbon content of 0.030%. This difference in carbon content gives 304L better weldability and reduces the risk of carbide precipitation during welding.

What is 304 wire mesh?

304 stainless steel wire mesh contains 18% chromium and 8% nickel, offering good corrosion resistance and durability. Compared to 316 stainless steel, which has 16% chromium, 10% nickel, and 2% molybdenum, 304 is less resistant to harsh environments but more cost-effective.

OTHER ALLOY STEEL

AVAILABLE MATERIAL

Related Products

- Stainless Steel 321/321h pipes and Stainless Steel 321/321h Tubes

- Stainless Steel 904l pipes and Stainless Steel 904l tubes

- Stainless Steel 446 Pipes and Stainless Steel 446 Tubes

- Stainless Steel 317/317l Pipes and Stainless Steel 317/317l Tubes

- Stainless Steel 304/304H Pipes And Tubes

- Stainless Steel 304L Pipes

- Stainless Steel 316/316L/316Ti Pipes and Stainless Steel 316/316L/316Ti Tubes

- Stainless Steel 310 Pipes and Stainless Steel 310 tubes

- Stainless Steel 347/347h Pipes & Stainless Steel 347/347h Tubes

- Stainless steel 304/304l/304h shims

- stainless steel 904l shims

- Stainless Steel 321/321H, 310/310S, 317/317L, 347/347H, 446 Shims

- Stainless steel 304/ 304l/304h perforated sheet

- Stainless Steel 904L Perforated Sheet

- Stainless Steel 304/304L/304H Wire mesh

- Stainless steel 904l wire mesh

- Stainless Steel 304/304l/304h Flanges

- stainless steel 904l Flanges

- 904l stainless steel plates and 904l stainless steel sheet

- 304/ 304l/ 304h stainless steel plates and 304/ 304l/ 304h stainless steel sheets

- 304/ 304l/ 304h compression tube fittings

- Stainless Steel 904l compression tube fittings

- Stainless Steel 904l olets

- Stainless Steel 304/ 304l, 304h Olets

- Stainless Steel 304/ 304l/ 304h Buttweld fittings

- Stainless Steels 904l Buttweld Fittings

- Stainless Steel 304/304L/304H Round Bars & Stainless Steel 304/304L/304H Wires

- Stainless Steel 904l Round Bars and Stainless Steel 904l Wires

- SS 321/ 321H Long radius Bends

- 304/304l/304h Long radius Bends

- Stainless Steel 316/316l/316ti Long Radius Bends

- Stainless Steel 317/ 317l Long Radius Bends

- Stainless Steel 347/347h Long Radius Bends

- Stainless Steel 446 Long radius bends

- Stainless Steel 904l Long Radius Bends

- SS 304/304l/304h Forged Fittings

- Stainless Steel 904L Forged Fittings

- Stainless Steel 316/316l/316ti Shims