Stainless Steel Wire Mesh Supplier

Table of Content

- Stainless Steel Wire Mesh

- Types of Stainless Steel Wire Mesh

- Stainless Steel Wire Mesh Specification

- Stainless Steel Wire Mesh Chemical Composition

- SS Wire Mesh Mechanical Properties

- Equivalent of Stainless Steel Wire Mesh

- Sizes of Stainless Steel Wire Mesh

- Stainless Steel Wire Mesh Weight Chart

- Application SS Wire Mesh

- FAQ

ASTM A580 SS 304 Wire Mesh Exporter, ASME SA580 310 Stainless Steel Wire Mesh,SS Wire Mesh, Stainless Steel Wire Mesh Manufacturer and Supplier in Europe.

Kalpataru Piping Solutions is a leading supplier of Stainless Steel Wire Mesh in the UK, recognized for its strong presence in the industry. With a wealth of experience in both business and technical aspects, we’ve established ourselves as a top manufacturer and supplier in the global market. We supply Stainless Steel Wire Mesh in a wide range of sizes and ship large quantities to various locations, meeting the growing demand for this product.

At Kalpataru Piping Solutions, our Stainless Steel Wire Mesh is highly sought after and widely used across different industries worldwide. We maintain a ready stock of these products in our warehouse, ensuring quick delivery to our clients. Every product undergoes rigorous in-house quality testing to ensure its durability and performance. Our manufacturing process adheres to International Quality Standards (IQS), solidifying our reputation as a leading manufacturer of Stainless Steel Wire Mesh, including grades such as 304L, 316L, 310, and 904L.

Stainless Steel Wire Mesh

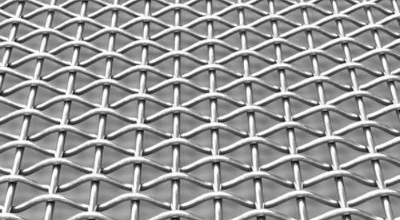

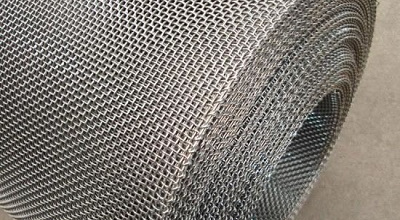

Stainless Steel Wire Mesh is manufactured from durable materials such as stainless steel, brass, or copper, which ensure a long service life. Available in various aperture sizes and thicknesses, our range is designed to meet the specific requirements of our clients. Known for its exceptional qualities, including high reliability, precise dimensions, and a smooth surface, Stainless Steel Wire Mesh is widely used in industries like chemical processing, construction, sugar production, and pharmaceuticals.

Types of Stainless Steel Wire Mesh

Stainless Steel Wire Mesh Specification

| Specification: | ASTM A580, A313 / ASME SA580, SA313 |

| Dimension: | ASTM, ASME, and API |

| Length : | Max 12000 mm |

| Diameter : | 5.5 – 400 mm |

| Types: | Square Wire Mesh, Welded Wire Mesh, Hexagonal Wire Mesh, Intermediate Wire Mesh, Tele Weave Wire Mesh, Fine Wire Mesh, Spring Steel Wire Mesh, Woven Wire Netting, Hex Wire Netting, Woven Wire Netting, Rockfall Netting, Plant Supporting Nets |

| Grade: | 304, 304L, 304H, 316, 316L, 317, 317L, 321, 310, 347, 904L Wire Mesh / Wire Netting ETC. |

Stainless Steel Wire Mesh Chemical Composition

| Material (ASTM) |

Chemical Composition(%) | ||||||||||

| P (MAX) |

Sl (MAX) |

C (MAX) |

Mn (MAX) |

Ni | N | S (MAX) |

Mo | Cr | Other | Cu | |

| 304L | 0.045 | 1 | 0.03 | 2 | 8.00~12 | – | 0.03 | – | 18.00~20 | – | – |

| 304 | 0.045 | 1 | 0.08 | 2 | 8.00~10.5 | – | 0.03 | – | 18.00~20 | – | – |

| 316 | 0.045 | 1 | 0.08 | 2 | 10.00~14 | – | 0.3 | 2.00~3 | 16.00~18 | – | – |

| 310s | 0.045 | 1.5 | 0.08 | 2 | 19.00~22 | – | 0.03 | – | 24.00~26 | – | – |

| 316L | 0.045 | 1 | 0.03 | 2 | 10.00~14 | – | 0.03 | 2.00~3 | 16.00~18 | – | – |

| 321 | 0.045 | 1 | 0.08 | 2 | 9.00~13 | – | 0.03 | – | 17.00~19 | Ti5xc | – |

| 309s | 0.045 | 0.75 | 0.08 | 2 | 12.00~15 | – | 0.03 | – | 22.00~24 | – | – |

| 317L | 0.045 | 1 | 0.03 | 2 | 11.00~15 | – | 0.03 | 3.00~4 | 18.00~20 | – | – |

| 317 | 0.045 | 1 | 0.08 | 2 | 10.00~14 | – | 0.03 | 3.00~4 | 18.00~20 | – | – |

| 430 | 0.04 | 0.75 | 0.12 | 1 | – | – | 0.03 | – | 16.00~18 | – | – |

SS Wire Mesh Mechanical Properties

| Grade | Yield Strength (0.2%Offset) | Melting Point | Density | Tensile Strength | Elongation |

| 304H | Psi 30000 , MPa 205 | 1400 °C (2550 °F) | 8.0 g/cm3 | Psi 75000 , MPa 515 | 40 % |

| 304/ 304L | Psi 30000 , MPa 205 | 1400 °C (2550 °F) | 8.0 g/cm3 | Psi 75000 , MPa 515 | 35 % |

| 306/ 316H | Psi 30000 , MPa 205 | 1400 °C (2550 °F) | 8.0 g/cm3 | Psi 75000 , MPa 515 | 35 % |

| 310 / 310S / 310H | Psi 30000 , MPa 205 | 1402 °C (2555 °F) | 7.9 g/cm3 | Psi 75000 , MPa 515 | 40 % |

| 317 | Psi 30000 , MPa 205 | 1400 °C (2550 °F) | 7.9 g/cm3 | Psi 75000 , MPa 515 | 35 % |

| 316L | Psi 30000 , MPa 205 | 1399 °C (2550 °F) | 8.0 g/cm3 | Psi 75000 , MPa 515 | 35 % |

| 347 | Psi 30000 , MPa 205 | 1454 °C (2650 °F) | 8.0 g/cm3 | Psi 75000 , MPa 515 | 35 % |

| 321 | Psi 30000 , MPa 205 | 1457 °C (2650 °F) | 8.0 g/cm3 | Psi 75000 , MPa 515 | 35 % |

| 904L | Psi 32000 , MPa 220 | 1350 °C (2460 °F) | 7.95 g/cm3 | Psi 71000 , MPa 490 | 35 % |

Equivalent of Stainless Steel Wire Mesh

| STANDARD | UNS | WERKSTOFF NR. | EN | JIS | GOST | BS | AFNOR |

| SS 304L | S30403 | 1.4306 / 1.4307 | X2CrNi18-9 / X2CrNi19-11 | SUS 304L | 03Х18Н11 | 3304S11 | Z3CN18‐10 |

| SS 304 | S30400 | 1.4301 | X5CrNi18-10 | SUS 304 | 08Х18Н10 | 304S31 | Z7CN18‐09 |

| SS 310 | S31000 | 1.4841 | X15CrNi25-20 | SUS 310 | 20Ch25N20S2 | 310S24 | – |

| SS 304H | S30409 | 1.4301 | – | – | – | – | – |

| SS 310S | S31008 | 1.4845 | X8CrNi25-21 | SUS 310S | 20Ch23N18 | 310S16 | – |

| SS 904L | N08904 | 1.4539 | X1NiCrMoCu25-20-5 | SUS 904L | STS 317J5L | 904S13 | Z2 NCDU 25-20 |

| SS 316 | S31600 | 1.4401 / 1.4436 | X5CrNiMo17-12-2 / X3CrNiMo17-13-3 | SUS 316 | – | 316S31 / 316S33 | Z7CND17‐11‐02 |

| SS 310H | S31009 | – | – | – | – | – | – |

| SS 316H | S31609 | 1.4401 | – | – | – | – | – |

| SS 316L | S31603 | 1.4404 / 1.4435 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 | SUS 316L | 03Ch17N14M3 / 03Ch17N14M2 | 316S11 / 316S13 | Z3CND17‐11‐02 / Z3CND18‐14‐03 |

| SS 316Ti | S31635 | 1.4571 | X6CrNiMoTi17-12-2 | SUS 316Ti | 08Ch17N13M2T | 320S31 | Z6CNDT17‐123 |

| SS 317L | S31703 | 1.4438 | X2CrNiMo18-15-4 | SUS 317L | – | – | – |

| SS 317 | S31700 | 1.4449 | – | SUS 317 | – | – | – |

| SS 321 | S32100 | 1.4541 | X6CrNiTi18-10 | SUS 321 | – | – | – |

| SS 347 | S34700 | 1.4550 | X6CrNiNb18-10 | SUS 347 | 08Ch18N12B | – | – |

| SS 321H | S32109 | 1.4878 | X12CrNiTi18-9 | SUS 321H | – | – | – |

| SS 347H | S34709 | 1.4961 | X6CrNiNb18-12 | SUS 347H | – | – | – |

Sizes of Stainless Steel Wire Mesh

| SWG | Mesh | WIRE DIAMETER | Approx Percentage Open Area | OPENING SIZE | |||

| MM | Inch | MM | Inch | Micron | |||

| 13 | 4 | 2.340 | 0.092 | 39.98 | 4.010 | 0.158 | 4,010 |

| 12 | 4 | 2.640 | 0.104 | 34.14 | 3.710 | 0.146 | 3,710 |

| 14 | 4 | 2.030 | 0.080 | 46,28 | 4.320 | 0.170 | 4.320 |

| 16 | 4 | 1.630 | 0.064 | 55.25 | 4.720 | 0.186 | 4,720 |

| 15 | 4 | 1.830 | 0.072 | 50.67 | 4.520 | 0.178 | 4,520 |

| 17 | 4 | 1.430 | 0.056 | 60.03 | 4.920 | 0.194 | 4,920 |

| 14 | 5 | 2.030 | 0.080 | 36.05 | 3.050 | 0.120 | 3,050 |

| 18 | 4 | 1.220 | 0.048 | 65.27 | 5.130 | 0.202 | 5,130 |

| 15 | 5 | 1.830 | 0.072 | 40.93 | 3.250 | 0.128 | 3,250 |

| 17 | 5 | 1.430 | 0.056 | 51.62 | 3.650 | 0.144 | 3650 |

| 16 | 5 | 1.630 | 0.064 | 46.12 | 3.450 | 0.136 | 3,450 |

| 18 | 5 | 1.220 | 0.048 | 57.74 | 3.860 | 0.152 | 3,860 |

| 20 | 5 | 0.910 | 0.036 | 67.38 | 4.170 | 0.164 | 4,170 |

| 19 | 5 | 1.020 | 0.040 | 63.87 | 4.060 | 0.160 | 4,060 |

| 16 | 6 | 1.630 | 0.064 | 37.82 | 2.603 | 0.102 | 2,603 |

| 19 | 6 | 1.020 | 0.040 | 57.62 | 3.213 | 0.127 | 3,213 |

| 17 | 6 | 1.430 | 0.056 | 43.85 | 2.803 | 0.110 | 2,803 |

| 20 | 6 | 0.910 | 0.036 | 61.63 | 3.323 | 0.131 | 3,323 |

| 16 | 8 | 1.630 | 0.064 | 23.68 | 1.545 | 0.061 | 1545 |

| 21 | 6 | 0.810 | 0.032 | 65.39 | 3.423 | 0.135 | 3,423 |

| 17 | 8 | 1.430 | 0.056 | 30.21 | 1.745 | 0.061 | 1,745 |

| 19 | 8 | 1.020 | 0.040 | 46.07 | 2.155 | 0.085 | 2,155 |

| 18 | 8 | 1.220 | 0.048 | 37.91 | 1.955 | 0.077 | 1,955 |

| 21 | 8 | 0.810 | 0.032 | 55.48 | 2.365 | 0.093 | 2,365 |

| 20 | 8 | 0.910 | 0.036 | 50.89 | 2.265 | 0.089 | 2,265 |

| 22 | 8 | 0.710 | 0.028 | 60.28 | 2.465 | 0.097 | 2,465 |

| 24 | 8 | 0.550 | 0.022 | 68.36 | 2.625 | 0.103 | 2,625 |

| 23 | 8 | 0.610 | 0.024 | 65.27 | 2.565 | 0.0101 | 2,565 |

| 25 | 8 | 0.500 | 0.020 | 70.98 | 2.675 | 0.105 | 2,675 |

| 21 | 10 | 0.810 | 0.032 | 46.39 | 1.730 | 0.068 | 1,730 |

| 20 | 10 | 0.910 | 0.036 | 41.18 | 1.630 | 0.064 | 1,630 |

| 22 | 10 | 0.710 | 0.028 | 51.91 | 1.830 | 0.072 | 1,830 |

| 24 | 10 | 0.550 | 0.022 | 61.38 | 1.990 | 0.078 | 1,990 |

| 23 | 10 | 0.610 | 0.024 | 57.74 | 1.930 | 0.076 | 1,930 |

| 25 | 10 | 0.500 | 0.020 | 64.50 | 2.040 | 0.080 | 2,040 |

| 23 | 12 | 0.610 | 0.024 | 50.67 | 1.507 | 0.059 | 1,507 |

| 22 | 12 | 0.710 | 0.028 | 44.16 | 1.407 | 0.055 | 1,407 |

| 24 | 12 | 0.550 | 0.022 | 54.78 | 1.567 | 0.062 | 1,567 |

| 26 | 12 | 0.450 | 0.018 | 62.00 | 1.667 | 0.066 | 1,667 |

| 25 | 12 | 0.500 | 0.020 | 58.34 | 1.617 | 0.064 | 1,617 |

| 24 | 14 | 0.550 | 0.022 | 48.56 | 1.264 | 0.050 | 1,264 |

| 26 | 14 | 0.450 | 0.018 | 56.55 | 1.364 | 0.054 | 1,364 |

| 25 | 14 | 0.500 | 0.020 | 52.48 | 1.314 | 0.052 | 1,314 |

| 27 | 14 | 0.400 | 0.016 | 60.77 | 1.414 | 0.056 | 1,414 |

| 24 | 16 | 0.550 | 0.022 | 42.71 | 1.038 | 0.041 | 1,038 |

| 28 | 14 | 0.370 | 0.015 | 63.37 | 1.444 | 0.057 | 1,444 |

| 25 | 16 | 0.500 | 0.020 | 46.93 | 1.088 | 0.043 | 1,088 |

| 27 | 16 | 0.400 | 0.016 | 55.96 | 1.188 | 0.047 | 1,188 |

| 26 | 16 | 0.450 | 0.018 | 51.34 | 1.138 | 0.045 | 1,138 |

| 29 | 16 | 0.340 | 0.013 | 61.75 | 1.248 | 0.049 | 1,248 |

| 25 | 18 | 0.500 | 0.020 | 41.69 | 0.911 | 0.036 | 911 |

| 30 | 16 | 0.310 | 0.012 | 64.76 | 1.278 | 0.050 | 1,278 |

| 26 | 18 | 0.450 | 0.018 | 46.39 | 0.961 | 0.038 | 961 |

| 28 | 18 | 0.370 | 0.015 | 54.43 | 1.041 | 0.041 | 1,041 |

| 27 | 18 | 0.400 | 0.016 | 51.34 | 1.011 | 0.040 | 1,011 |

| 24 | 20 | 0.550 | 0.022 | 32.14 | 0.720 | 0.028 | 720 |

| 26 | 20 | 0.450 | 0.018 | 41.69 | 0.820 | 0.032 | 820 |

| 25 | 20 | 0.500 | 0.020 | 36.76 | 0.770 | 0.030 | 770 |

| 27 | 20 | 0.400 | 0.016 | 46.93 | 0.870 | 0.034 | 870 |

| 29 | 20 | 0.340 | 0.013 | 53.62 | 0.930 | 0.037 | 930 |

| 28 | 20 | 0.370 | 0.015 | 50.22 | 0.900 | 0.035 | 900 |

| 30 | 20 | 0.310 | 0.012 | 57.14 | 0.960 | 0.038 | 960 |

| 28 | 24 | 0.370 | 0.015 | 42.30 | 0.688 | 0.027 | 688 |

| 27 | 24 | 0.400 | 0.016 | 38.69 | 0.658 | 0.026 | 658 |

| 30 | 24 | 0.310 | 0.012 | 50.00 | 0.748 | 0.029 | 748 |

| 29 | 24 | 0.340 | 0.013 | 46.07 | 0.718 | 0.028 | 718 |

| 32 | 24 | 0.270 | 0.011 | 55.48 | 0.788 | 0.031 | 788 |

| 29 | 30 | 0.340 | 0.013 | 35.81 | 0.507 | 0.020 | 507 |

| 28 | 30 | 0.370 | 0.015 | 31.70 | 0.477 | 0.019 | 477 |

| 30 | 30 | 0.310 | 0.012 | 40.18 | 0.537 | 0.021 | 537 |

| 32 | 30 | 0.270 | 0.011 | 46.39 | 0.557 | 0.023 | 577 |

| 31 | 30 | 0.290 | 0.011 | 43.23 | 0.557 | 0.022 | 557 |

| 32 | 40 | 0.270 | 0.011 | 33.04 | 0.365 | 0.014 | 365 |

| 34 | 40 | 0.234 | 0.009 | 39.88 | 0.401 | 0.016 | 401 |

| 33 | 40 | 0.250 | 0.010 | 36.76 | 0.385 | 0.015 | 385 |

| 35 | 40 | 0.210 | 0.008 | 44.80 | 0.425 | 0.017 | 425 |

| 34 | 50 | 0.234 | 0.009 | 29.09 | 0.274 | 0.011 | 274 |

| 36 | 40 | 0.193 | 0.008 | 48.45 | 0.442 | 0.017 | 442 |

| 35 | 50 | 0.210 | 0.008 | 34.41 | 0.298 | 0.012 | 298 |

| 37 | 50 | 0.172 | 0.007 | 43.75 | 0.336 | 0.013 | 336 |

| 36 | 50 | 0.193 | 0.008 | 38.45 | 0.315 | 0.012 | 315 |

| 38 | 50 | 0.152 | 0.006 | 49.11 | 0.356 | 0.014 | 356 |

| 37 | 60 | 0.172 | 0.007 | 32.25 | 0.251 | 0.010 | 251 |

| 38 | 60 | 0.152 | 0.006 | 41.08 | 0.271 | 0.011 | 271 |

| 36 | 60 | 0.193 | 0.008 | 29.60 | 0.230 | 0.009 | 230 |

| 38 | 80 | 0.152 | 0.006 | 21.17 | 0.166 | 0.007 | 166 |

| 40 | 80 | 0.122 | 0.005 | 37.91 | 0.196 | 0.008 | 196 |

| 39 | 80 | 0.130 | 0.005 | 34.88 | 0.188 | 0.007 | 188 |

| 41 | 80 | 0.112 | 0.004 | 41.89 | 0.206 | 0.008 | 206 |

| 42 | 100 | 0.102 | 0.004 | 35.81 | 0.152 | 0.006 | 152 |

| 42 | 80 | 0.102 | 0.004 | 46.07 | 0.216 | 0.008 | 216 |

| 43 | 100 | 0.091 | 0.004 | 41.18 | 0.163 | 0.006 | 163 |

| 44 | 120 | 0.081 | 0.003 | 38.11 | 0.131 | 0.005 | 131 |

| 44 | 100 | 0.081 | 0.003 | 46.39 | 0.173 | 0.007 | 173 |

| 45 | 150 | 0.071 | 0.003 | 33.72 | 0.098 | 0.004 | 98 |

| 47 | 200 | 0.050 | 0.002 | 36.76 | 0.077 | 0.003 | 77 |

| 45.5 | 150 | 0.063 | 0.002 | 39.43 | 0.106 | 0.004 | 106 |

| 48 | 250 | 0.040 | 0.002 | 36.76 | 0.062 | 0.002 | 62 |

| 48.5 | 325 | 0.035 | 0.001 | 30.49 | 0.043 | 0.002 | 43 |

| 48 | 300 | 0.040 | 0.002 | 27.83 | 0.045 | 0.002 | 45 |

| 49.5 | 400 | 0.028 | 0.001 | 31.25 | 0.036 | 0.001 | 36 |

| 50 | 500 | 0.025 | 0.001 | 25.79 | 0.026 | 0.001 | 26 |

Stainless Steel Wire Mesh Weight Chart

| Roll Size | Per 100 Square Feet Weight | Wire Size | Gauge | Weight Of Roll |

| 5’ x 150’ | 30 lbs. | W2.1/W2.1 | 8/8 | 225 lbs. |

| 5′ x 150′ | 21 lbs. | W1.4/W1.4 | 10/10 | 157 lbs. |

| 5’ x 150’ | 42 lbs. | W2.9/W2.9 | 6/6 | 315 lbs. |

| Spacing | Wire Size | Gauge | Per 100 Square Feet Weight |

| 6 x 6 | W2.1/W2.1 | 8/8 | 30 lbs. |

| 4 x 4 | W2.9/W2.9 | 6/6 | 62 lbs. |

| 6 x 6 | W1.4/W1.4 | 10/10 | 21 lbs. |

| 6 x 6 | W4/W4 | 4/4 | 58 lbs. |

| 6 x 6 | W2.9/W2.9 | 6/6 | 42 lbs. |

| 4 x 4 | W4/W4 | 4/4 | 85 lbs. |

Application SS Wire Mesh

- Food processing

- Cement industry

- Mineral industry

- Construction site

- Fertilizer industry

We Export To Stainless Steel Pipes & Tubes

New Zealand, Ukraine, Brazil, Azerbaijan, Angola, United Kingdom, Philippines, Oman, France, Algeria, Macau, Sri Lanka, Tibet, Norway, Mexico, Venezuela, Denmark, Russia, Bhutan, Estonia, Austria, Vietnam, Argentina, Turkey, Greece, Romania, Bahrain, Bangladesh, Afghanistan, Italy, Poland, Zimbabwe, Thailand, India, Kenya, Ecuador, Puerto Rico, Nepal, Malaysia, Bulgaria, Libya, Slovakia, Chile, Serbia, Australia, Poland, Iran, Costa Rica, Peru, South Korea, Iraq, Iran, Indonesia, Spain, Trinidad & Tobago,Tunisia, Qatar, Japan, Canada, Taiwan, Yemen, Mongolia, Czech Republic, Israel, Ghana, Egypt, Nigeria, Saudi Arabia, United Arab Emirates, Namibia, Hungary, South Africa, Hong Kong, Croatia, Colombia, Lebanon, Nigeria, Portugal, Finland, Pakistan, Jordan, Sweden, Belgium, Gambia, Lithuania, United States, Chile, Bolivia, Germany, Singapore, Ireland, Gabon, Kuwait, Switzerland, Mexico, Belarus, Kazakhstan, Morocco, China, Netherlands, Germany, Belgium, Italy, Turkey, Denmark and UK.

FAQ

What is stainless steel wire mesh?

Stainless steel wire mesh is made by weaving stainless steel wires into a grid-like pattern. The mesh can vary in weave patterns and density, allowing for different properties, such as strength, flexibility, and filtration capabilities. It is commonly used in industrial, architectural, and filtration applications.

Which wire mesh is best?

Stainless steel wire mesh is considered one of the best options due to its strength, durability, and resistance to corrosion. It offers stable and precise pore sizes, making it suitable for various applications. Available in high-carbon and low-carbon variants, it also comes in different weave patterns to meet specific needs.

How long does stainless steel mesh last?

Stainless steel mesh can last anywhere from a year in harsh, wet, or coastal environments to several decades in more favorable conditions, such as desert locations. Under ideal circumstances, it could potentially last up to a century. The longevity is significantly enhanced with premium alloys like T-316, known for its superior resistance to rust and corrosion.

Related Products

- Alloy Steel P22 Buttweld Fitting

- Alloy Steel P11 Buttweld Fitting

- Alloy Steel P5 Buttweld Fitting

- Alloy Steel P9 Buttweld Fitting

- Alloy Steel P91 Buttweld Fitting

- Alloy Steel p12 Buttweld Fitting

- Alloy Steel F22 Forged Fitting

- Alloy Steel F11 Forged Fitting

- Alloy Steel F5 Forged Fitting

- Alloy Steel F9 Forged Fitting

- Alloy Steel F91 Forged Fitting

- Alloy Steel F12 Forged Fitting

- Alloy Steel P22 Plates & Alloy Steel P22 Sheets

- Alloy Steel P11 Plates & Alloy Steel P11 Sheets

- Alloy Steel P5 Plates & Alloy Steel P5 Sheets

- Alloy Steel P9 Plates & Alloy Steel P9 Sheet

- Alloy Steel P22 Round Bars & Alloy Steel P22 Wires

- Alloy Steel P11 Round Bars & Alloy Steel P11 Wires

- Alloy Steel P5 Round Bars & Alloy Steel P5 Wires

- Alloy Steel F9 Round Bars & Alloy Steel F9 Wires

- Alloy Steel F91 Round Bars & Alloy Steel F91 Wires

- Alloy Steel F12 Round Bars & Alloy Steel F12 Wires

- Alloy Steel F22 Flanges

- Alloy Steel F11 Flanges

- Alloy Steel F5 Flanges

- Alloy Steel F9 Flanges

- Alloy Steel F91 Flanges

- Alloy Steel F12 Flanges

- Alloy Steel F22 Olets

- Alloy Steel F11 Olet

-

- Alloy Steel P12 Plates & Alloy Steel P12 Sheets

- Alloy Steel P22 Long Radius Bend

- Alloy Steel P11 Long Radius Bends

- Alloy Steel P5 Long Radius Bends

- Alloy Steel P9 Long Radius Bends

- Alloy Steel P91 Long Radius Bends

- Alloy Steel P12 Long Radius Bends

- Alloy Steel P22 Pipes & Alloy Steel P22 Tubes

- Alloy Steel P11 Pipes & Alloy Steel P11 Tubes

- Alloy Steel P5 Pipes & Alloy Steel P5 Tubes

- Alloy Steel P9 Pipes & Alloy Steel P9 Tubes

- Alloy Steel P91 Pipes & Alloy Steel P91 Tubes

- Alloy Steel P12 Pipes & Alloy Steel P12 Tubes

- Alloy Steel F5 Olets

- Alloy Steel F91 Olets

- Alloy Steel F12 Olets

- Alloy Steel F9 Olets