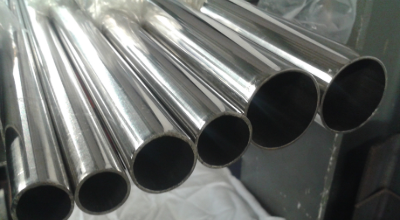

Super Duplex Stainless Steel Pipes and Tubes

Table of Content

- Super Duplex Stainless Steel Pipe and Tube Manufacturer in India

- Super Duplex Pipe Specifications

- Types of Super Duplex Steel Pipes & Tubes

- Super Duplex Stainless Steel Pipes and Tubes Chemical Composition

- Super Duplex Stainless Steel Tube Mechanical Properties

- Applications of Super Duplex Pipes & Tubes

- We Export To Super Duplex Steel Pipes & Tubes

- FAQs

Super Duplex Stainless Steel Pipe and Tube Manufacturer in India

At Kalpataru Piping Solutions, we specialize in providing Super Duplex Tubes that meet international specifications. Our extensive product knowledge and dedication to quality enable us to deliver accurate and reliable products. We pride ourselves on offering competitive prices, high-quality materials, and on-time delivery, making us one of the most trusted suppliers of Super Duplex Pipes in India.

Super Duplex Tubes, including grades UNS S32750 and S32760, offer excellent machinability and weldability. These materials comply with ASME B36.19 standards, ensuring precise dimensions, wall thickness, and weight specifications. With their unique properties, these pipes are widely used in demanding applications across various industries.

As a leading manufacturer, Kalpataru Piping Solutions produces high-quality Super Duplex Steel Pipes and Tubes. The material’s high chromium and molybdenum content provides superior corrosion resistance compared to standard duplex grades. This advantage, coupled with lower alloying costs compared to austenitic and ferritic grades, makes Super Duplex an economical and effective choice for many projects.

Super Duplex Steel also boasts exceptional tensile and yield strength while maintaining good toughness and ductility. These qualities make it ideal for use in challenging environments such as the oil and gas industry, offshore platforms, chemical processing equipment, pressure vessels, boilers, and heat exchangers.

By choosing Kalpataru Piping Solutions, you benefit from high-quality products designed to meet your specific needs. Contact us today to learn more about our range of Super Duplex Steel Pipes and Tubes.

Super Duplex Pipe Specifications

| Specifications | ASTM A 789 ASME SA 789 |

| Standard | AISI, DIN, EN, GB, JIS, ASTM, ASME Super Duplex 2507 Pipe |

| 2507 Seamless Pipe Outer Diameter | 6.00 mm OD up to 250 mm OD, Sizes up to 12” NB |

| Alloy 2507 Welded Pipe size | 5.0 mm – 1219.2 mm |

| 2507 EFW Pipe size | 5.0 mm – 1219.2 mm |

| Thickness | 0.3mm – 50 mm |

| SS 2507 Seamless Tube Size | 3.35 mm OD To 101.6 mm OD, 15 NB to 150 NB IN |

| 2507 Welded Tube Size | 6.35 mm OD To 152 mm OD |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| DSS 2507 tubing wall thickness | 0.020″ –0.220″ (special wall thicknesses available) |

| 2507 Pipe Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Duplex 2507 Pipe & Tube Finish | Polished, AP (Annealed & Pickled), MF, NO.1, NO.4, BA (Bright & Annealed), 2B, BA, HL, 8K, Mirror finish,etc |

| 2507 Pipe & Tube Form | Round, Hollow, Square,Rectangular, Hydraulic, Coiled, Straight Pipes, “U” Shape, Pan Cake Coils etc. |

| Super Duplex 2507 Pipe & Tube Length | Single Random, Double Random, Standard & Cut length |

| 2507 Pipe & Tube End | Beveled End,Plain End, Treaded. |

| 2507 Pipe & Tube Type | 2507 Seamless / ERW/ Welded / Fabricated / EFW / CDW / DOM / CEW Pipes |

| Marking | All 2507 Pipes are marked as follows: Grade, Standard, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Super Duplex 2507 Tube Application | Oil Tube, Gas Tube, Fluid Tube, Boiler and Heatexchanger |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Specialized in | Large Dia 2507 Pipe 2507 Capillary Tube & Other Odd Size 2507 Super Duplex Heat Exchanger & Condenser Tubes |

| Material Test Certificates (MTC) | Material Test Certificates (MTC) as per EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2, 100% Radiography Test Report, Raw Materials Certificate, Third Party Inspection Report, Fumigation Certificates, Heat Treatment Charts, 2507 Tubes HS Code Commercial Invoice, Form A for Generalized System of Preferences (GSP), Manufacturer Test Certificate , Laboratory Test Certificate from Govt. Approved Lab. |

| We can also cut, thread, and groove Super Duplex 2507 Pipes & Tubes to meet your specifications. | |

Types of Super Duplex Steel Pipes & Tubes

Super Duplex Stainless Steel Pipes and Tubes Chemical Composition

| Element | S32750 | S32750 |

| C | 0.030 max | 0.05 max |

| Mn | 1.20 max | 1.00 max |

| Si | 0.80 max | 1.00 max |

| P | 0.035 max | 0.030 max |

| S | 0.020 max | 0.010 max |

| Cr | 24.00 – 26.00 | 24.00 – 26.00 |

| Mo | 3.00 – 5.00 | 3.00 – 5.00 |

| Ni | 6.00 – 8.00 | 6.00 – 8.00 |

| N | 0.24 – 0.32 | 0.20 – 0.30 |

| Fe | 58.095 min | 57.61 min |

Super Duplex Stainless Steel Tube Mechanical Properties

| Element | S32750 / S32760 |

| Density (g/cm 3) | 7.8 |

| Density (lb/in 3) | 0.281 |

| Melting Point (°C) | 1350 |

| Melting Point (°F) | 2460 |

Applications of Super Duplex Pipes & Tubes

Super Duplex S32750/S32760 pipes and tubes offer exceptional corrosion resistance, especially in environments with high levels of chloride. These materials are commonly used in industries that require superior performance in harsh conditions.

The key applications of Super Duplex Steel include:

- Desalination Equipment: Ideal for seawater desalination plants due to their resistance to chloride-induced corrosion.

- Chemical Process Equipment: Suitable for chemical process pressure vessels, piping, and heat exchangers, ensuring durability and longevity.

- Marine Applications: Used in marine environments for offshore platforms, shipbuilding, and other marine structures.

- Flue Gas Scrubbing Equipment: Effective in scrubbers used to control air pollution from industrial processes.

- Pulp & Paper Mill Equipment: Provides corrosion resistance in the harsh conditions of pulp and paper mills.

- Offshore Oil Production/Technology: Essential for offshore platforms, ensuring reliable performance under extreme conditions.

- Oil and Gas Industry Equipment: Used in refineries, petrochemical plants, and other oil and gas industry equipment where durability and corrosion resistance are critical.

Super Duplex S32750/S32760 pipes and tubes are designed to withstand the most challenging environments, offering superior strength and corrosion resistance.

We Export To Super Duplex Steel Pipes & Tubes

New Zealand, Ukraine, Brazil, Azerbaijan, Angola, United Kingdom, Philippines, Oman, France, Algeria, Macau, Sri Lanka, Tibet, Norway, Mexico, Venezuela, Denmark, Russia, Bhutan, Estonia, Austria, Vietnam, Argentina, Turkey, Greece, Romania, Bahrain, Bangladesh, Afghanistan, Italy, Poland, Zimbabwe, Thailand, India, Kenya, Ecuador, Puerto Rico, Nepal, Malaysia, Bulgaria, Libya, Slovakia, Chile, Serbia, Australia, Poland, Iran, Costa Rica, Peru, South Korea, Iraq, Iran, Indonesia, Spain, Trinidad & Tobago,Tunisia, Qatar, Japan, Canada, Taiwan, Yemen, Mongolia, Czech Republic, Israel, Ghana, Egypt, Nigeria, Saudi Arabia, United Arab Emirates, Namibia, Hungary, South Africa, Hong Kong, Croatia, Colombia, Lebanon, Nigeria, Portugal, Finland, Pakistan, Jordan, Sweden, Belgium, Gambia, Lithuania, United States, Chile, Bolivia, Germany, Singapore, Ireland, Gabon, Kuwait, Switzerland, Mexico, Belarus, Kazakhstan, Morocco, China, Netherlands, Germany, Belgium, Italy, Turkey, Denmark and UK.

FAQ

What is a super duplex pipe?

Super duplex pipes combine high strength from the ferritic structure and excellent corrosion resistance from the austenitic structure, along with superior resistance to stress corrosion cracking.

What is super duplex tubing?

Super duplex tubing, like S32750, features a mixed microstructure of austenite and ferrite, offering enhanced strength and corrosion resistance compared to traditional ferritic and austenitic steels.