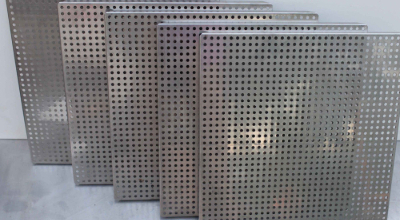

Super Duplex Steel Products

Super Duplex Steel Plates, Super Duplex Steel Forged Fittings Stockist, Super Duplex Steel Flanges, Super Duplex Steel Pipes Manufacturer, super duplex steel grades, Super Duplex Steel UNS S2502 Buttwelded Fittings Manufacturers.

Super Duplex Stainless Steel is a type of stainless steel made from an approximately equal mix of austenitic and ferritic steel. This unique composition provides exceptional strength, excellent ductility, and superior resistance to corrosion, making it a better choice compared to the 300 and 400 series stainless steels.

Our range of Super Duplex Stainless Steel products is suitable for various industries, including aerospace, automotive, manufacturing, oil and gas, and more. Whether your project demands high performance, durability, or resistance to harsh environments, SDSS is an ideal solution.

Looking for high-quality Super Duplex Stainless Steel? Contact us today to explore our offerings. Our team is ready to assist you with your specific requirements!

Types of Super Duplex Product

Super Duplex Steel Composition

| Element | Min % | Max % |

| C | – | 0.03 |

| Mn | – | 1.2 |

| Si | – | 0.80 |

| S | – | 0.015 |

| P | – | 0.035 |

| Cr | 24.0 | 26.0 |

| Ni | 6.0 | 8.0 |

| Mo | 3.0 | 4.5 |

| N | 0.24 | 0.35 |

| Cu | – | 0.5 |

| Fe | bal |

We Export To Super Duplex Steel Products

New Zealand, Ukraine, Brazil, Azerbaijan, Angola, United Kingdom, Philippines, Oman, France, Algeria, Macau, Sri Lanka, Tibet, Norway, Mexico, Venezuela, Denmark, Russia, Bhutan, Estonia, Austria, Vietnam, Argentina, Turkey, Greece, Romania, Bahrain, Bangladesh, Afghanistan, Italy, Poland, Zimbabwe, Thailand, India, Kenya, Ecuador, Puerto Rico, Nepal, Malaysia, Bulgaria, Libya, Slovakia, Chile, Serbia, Australia, Poland, Iran, Costa Rica, Peru, South Korea, Iraq, Iran, Indonesia, Spain, Trinidad & Tobago,Tunisia, Qatar, Japan, Canada, Taiwan, Yemen, Mongolia, Czech Republic, Israel, Ghana, Egypt, Nigeria, Saudi Arabia, United Arab Emirates, Namibia, Hungary, South Africa, Hong Kong, Croatia, Colombia, Lebanon, Nigeria, Portugal, Finland, Pakistan, Jordan, Sweden, Belgium, Gambia, Lithuania, United States, Chile, Bolivia, Germany, Singapore, Ireland, Gabon, Kuwait, Switzerland, Mexico, Belarus, Kazakhstan, Morocco, China, Netherlands, Germany, Belgium, Italy, Turkey, Denmark and UK.

FAQs

What are super duplex materials?

Super duplex steels are high-performance alloys with about 25% chromium content. They feature a microstructure consisting of both austenitic and ferritic phases, combining the benefits of both to offer high strength, excellent corrosion resistance, and improved durability.

What is the grade of super duplex steel?

Super duplex steels, such as F53 (UNS S32750) and F55 (UNS S32760), fall within the PREN (Pitting Resistance Equivalent Number) range of 38-45. These grades are known for their enhanced corrosion resistance and high mechanical strength due to their high chromium, molybdenum, and nitrogen content.

What is Super duplex stainless steel?

Super duplex stainless steel is a high-performance material characterized by its dual-phase microstructure of austenitic and ferritic grains. It offers exceptional strength and superior corrosion resistance, making it suitable for demanding applications in harsh environments.

What is super duplex steel?

Super duplex steel is a high-performance stainless steel containing approximately 25% chromium, with a dual-phase microstructure of austenitic and ferritic grains, offering exceptional strength and corrosion resistance.

OTHER ALLOY STEEL

AVAILABLE MATERIAL

Related Products

- Duplex Steel UNS S31803 Plates and Duplex Steel UNS S31803 Sheets

- Duplex Steel UNS S32205 Plates and Duplex Steel UNS S32205 Sheets

- Duplex Steel UNS S31803 Buttweld Fittings

- Duplex Steel UNS S32205 Buttweld Fittings

- Duplex Steel UNS S31803 Forged Fittings

- Duplex Steel UNS S32205 Forged Fittings

- Duplex Steel UNS S32205 Instrumentation Valve